Trust the Pro’s When Selecting The Right Tank Liquid Level Sensor

For a variety of reasons, selecting the proper liquid level sensor for chemical tank applications is critical.

To begin, chemical tanks frequently contain highly corrosive or abrasive compounds that can harm or destroy traditional-level sensors. Submersible level sensors, on the other hand, are resistant to extreme environments and conditions, making them perfect for use in chemical tanks. They are often composed of materials that can withstand corrosion and erosion induced by chemical compounds, such as stainless steel or titanium.

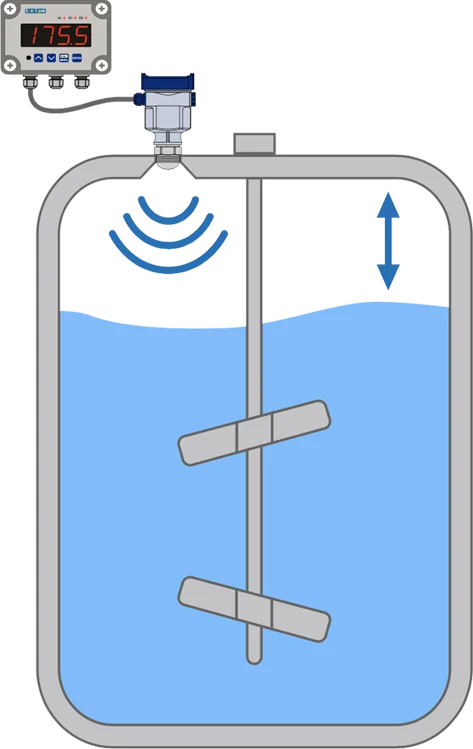

Second, chemical tanks frequently have unique measurement requirements, such as high precision or the ability to test materials with high viscosity or low dielectric constant. Submersible level sensors can accurately monitor the level of a liquid or solid in a tank, even if the material being measured is highly viscous or has a low dielectric constant. This is because the sensor is immersed in the liquid, allowing for more direct measurement.

Third, chemical tanks frequently run at high pressures or temperatures, which can interfere with other forms of level sensors. Submersible level sensors can function normally in these settings, making them appropriate for use in chemical tanks.

Fourth, chemical tanks frequently require maintenance and cleaning, which can be time-consuming and expensive. Submersible level sensors are simple to install and maintain since they may be installed directly in the tank, without the need for external pipes or mounting brackets. Furthermore, they are normally sealed, making them resistant to dust and other impurities.

Finally, chemical tanks may have unique safety needs, such as the detection of leaks or overfill conditions. Submersible level sensors can give accurate and dependable level measurements, which can be utilized to identify leaks or overfills and so protect human health and the environment.

Finally, choosing the appropriate liquid level sensor for chemical tank applications is critical for guaranteeing the safe and effective operation of these tanks. Because of their ability to survive severe environments, make precise measurements, function under high pressure and temperature settings, and be simple to install and maintain, submersible level sensors are the best choice for these applications. They can also provide vital safety features like leak detection, which is essential in chemical tank applications.

Learn more about liquid level sensors

Please contact us to discuss your application