Best Chemical Level Sensor Installation Practices

The following procedures are normally necessary to instal a chemical level sensor in a chemical tank:

The first stage in the preparation process is to clean the tank completely and check that it is free of any debris or foreign objects. Before installing the chemical level sensor, the tank should be examined for any leaks or damage that may need to be fixed.

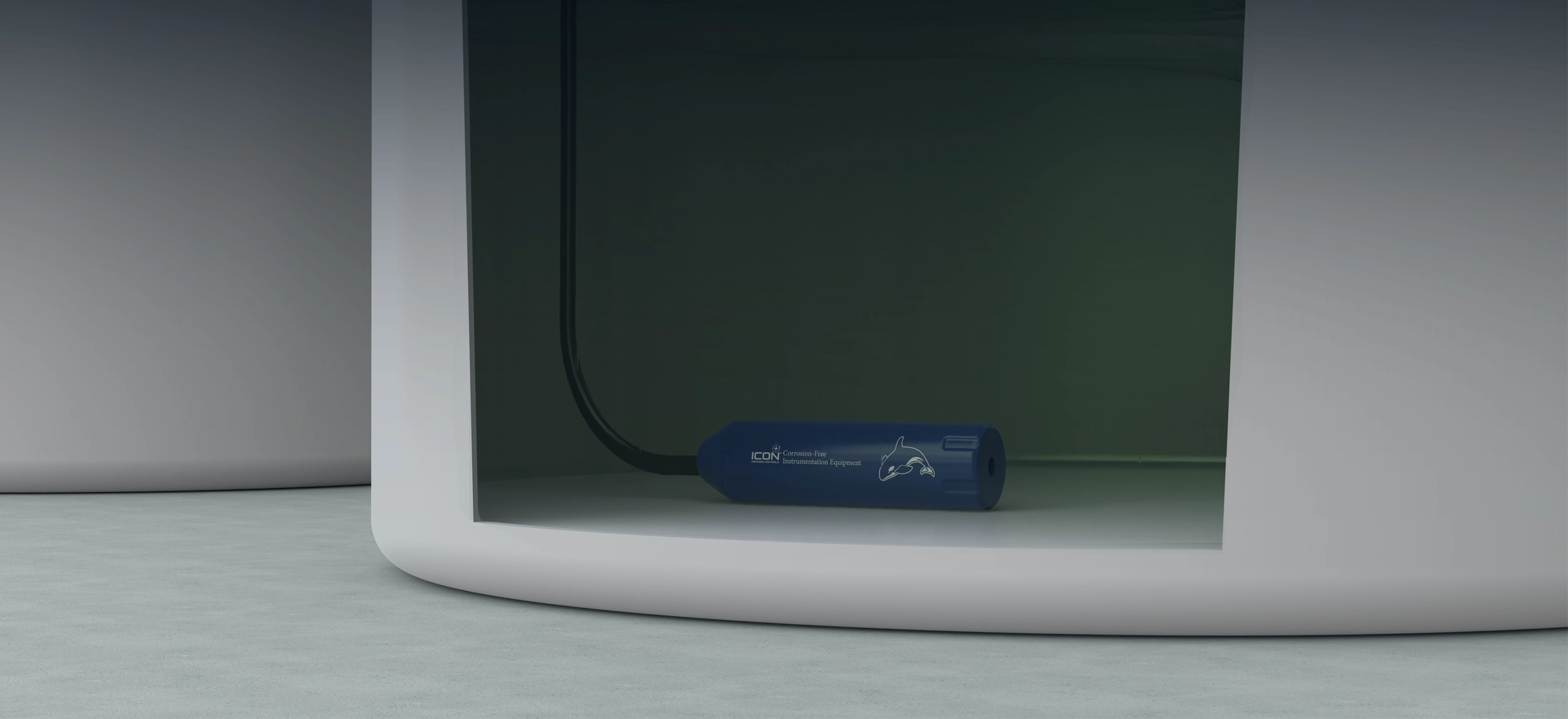

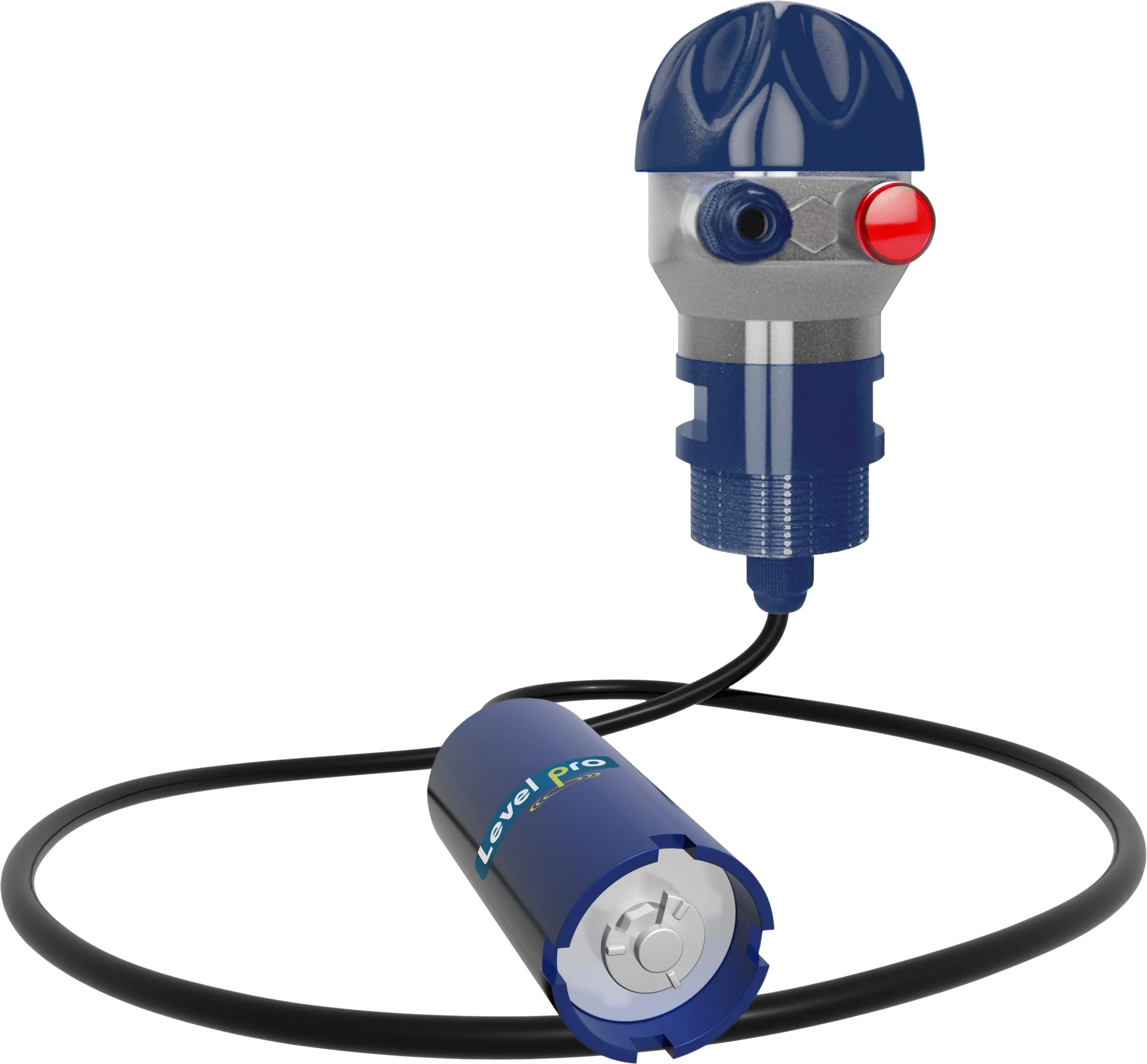

Selecting the Appropriate Sensor: The next step is to select the sensor that is best suited for the particular chemical and tank environment. Different sensors are made to function with various substances and in various settings. For bulk chemicals, for instance, submersible chemical level sensors are a useful option because they may be totally submerged in the liquid without being harmed.

Installing the Sensor: After selecting the correct chemical level sensor, it must be installed in the tank. It might be necessary to drill holes in the tank or attach the sensor to an existing fitting to accomplish this. To guarantee reliable readings, the sensor needs to be positioned at the proper height and level.

The sensor must then be connected to a local or remote controller, which will interpret the output signal from the sensor, for wiring and calibration. To make sure it is producing reliable results, the sensor must also be calibrated. This can entail modifying the sensor’s sensitivity or making additional modifications as required.

Connecting Power and Signal: The sensor requires a power source and a signal output, with 4-20 mA being the most popular. The local or remote controller, which may be used to monitor and control the level of the chemical in the tank, is then connected to the signal output from the chemical level sensor.

Testing and Upkeep: To make sure the chemical level sensor is giving correct data and to keep it in excellent working order, it should be regularly tested and maintained. Cleaning the sensor and inspecting it for wear or damage may be necessary.

It’s vital to remember that the chemical level sensor’s material selection affects how it is installed in a significant way. For instance, chemical level sensors constructed of PVC or PP are lightweight and simple to instal, whereas PVDF or stainless steel sensors could need more specialist installation tools.

Overall, installing a chemical level sensor in a tank of chemicals requires careful planning, wise sensor selection, and adherence to manufacturer’s recommendations. To guarantee that the sensor is giving accurate and dependable readings, regular maintenance is also necessary.

Learn more about chemical level sensors

Please contact us to discuss your application