What Makes A Great Radar Tank Liquid Level Sensor?

There are a number of things to take into account when choosing a radar level sensor to make sure it can deliver precise, high-accuracy and reliable data for the intended application.

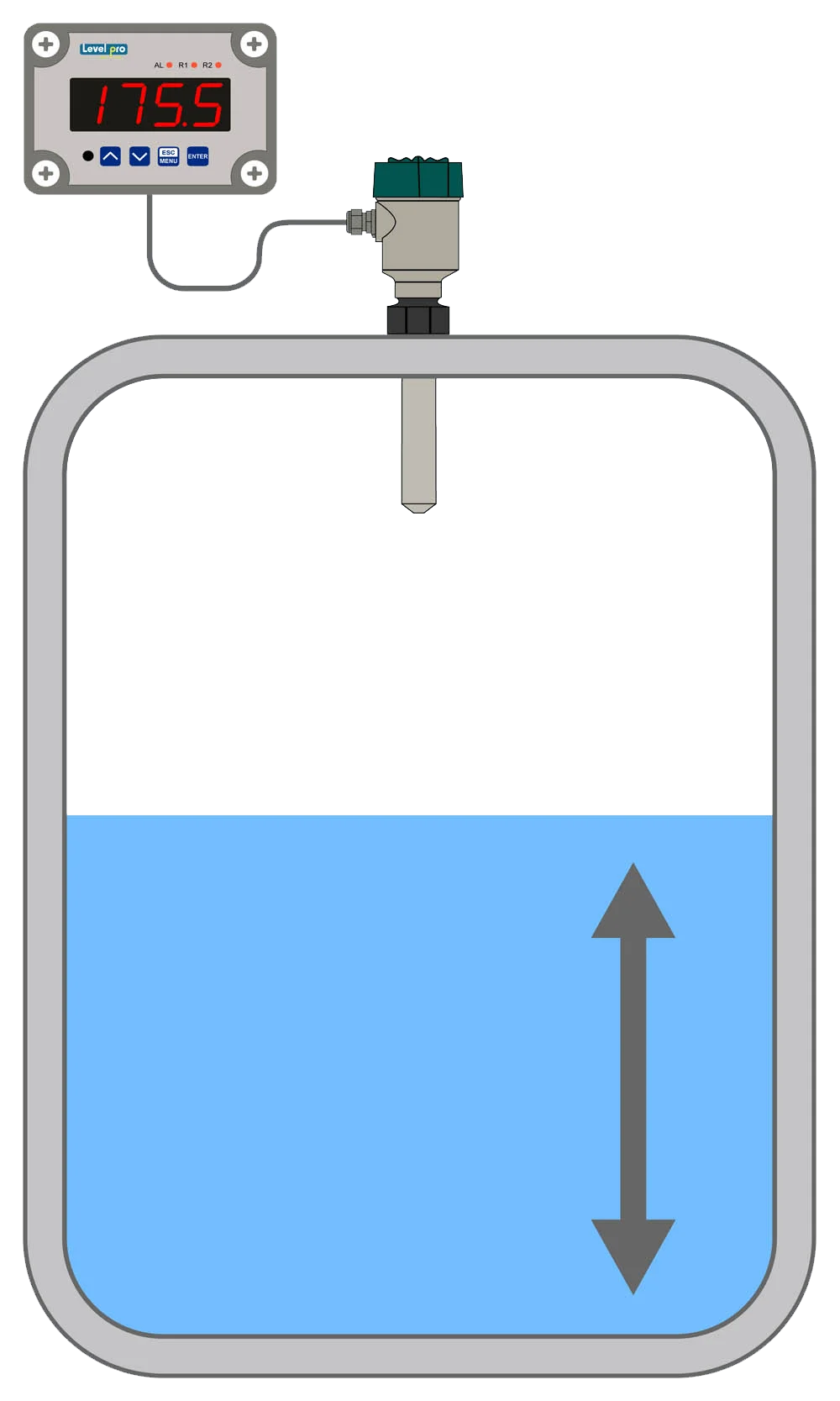

Operating range: The radar sensor’s operating range is a crucial factor since it establishes the distance between the sensor and the surface of the object being monitored. It is crucial to choose a sensor that can correctly measure the amount of the material and has a range that is suitable for the application in question.

Operating frequency: Different frequencies are used by radar level sensors, and the frequency selected will depend on the application. In applications where highly reflective materials, including liquids and powders, are being evaluated, 26GHz radar sensors are frequently utilised. For situations where the substance being evaluated is less reflective, such as granular or bulk materials, 80GHz radar sensors are commonly employed. The lower wavelength and higher detection resolution of 80GHz radar sensors allow them to see through dust, steam, and foam.

Measurement accuracy: The radar sensor’s measurement accuracy is a crucial factor since it affects the sensor’s capacity to precisely estimate the material’s level. It is crucial to choose a sensor with high measurement accuracy and the capacity to deliver reliable measurements.

Temperature and pressure range: The radar sensor’s temperature and pressure range must also be taken into account because they affect the conditions in which the sensor can operate. It is crucial to pick a sensor that can function within the application’s particular temperature and pressure range.

Options for installing the radar sensor: The radar sensor’s mounting options must be taken into account because they will affect where and how the sensor can be installed. It’s crucial to pick a sensor that can be quickly and simply fitted in the required location and has a range of mounting choices, such as flange, thread, or rod.

Some radar level sensors can connect with other devices, like as PLCs and control systems, and they can also be integrated into larger systems. It is important to take into account and complement the existing system with the communication interface and protocol.

In conclusion, it is crucial to take into account the operating frequency, measurement precision, temperature and pressure range, mounting options, communication, and integration when choosing a radar level sensor. While 80GHz radar sensors are frequently employed for applications where the material being measured is less reflecting, such as granular or bulk materials, 26GHz radar sensors are typically utilised when the material being measured is highly reflective, such as liquids and powders. The lower wavelength and higher detection resolution of 80GHz radar sensors allow them to see through dust, steam, and foam.

Learn more about level sensors

Please contact us to discuss your application