Submersible Level Sensor An Excellent Choice For Tank Level Monitoring

Because they are dependable, accurate, and simple to instal, submersible level sensors are the top choice among bulk chemical suppliers and are widely used for remote tank level monitoring. They can measure the entire liquid level in a tank without any deadband because they are made to be entirely submerged in the liquid. This implies that they can measure the liquid level continuously and precisely independent of the tank’s size or shape. In addition to being useful in severe situations, submersible level sensors can detect a variety of liquids, including corrosive and viscous fluids.

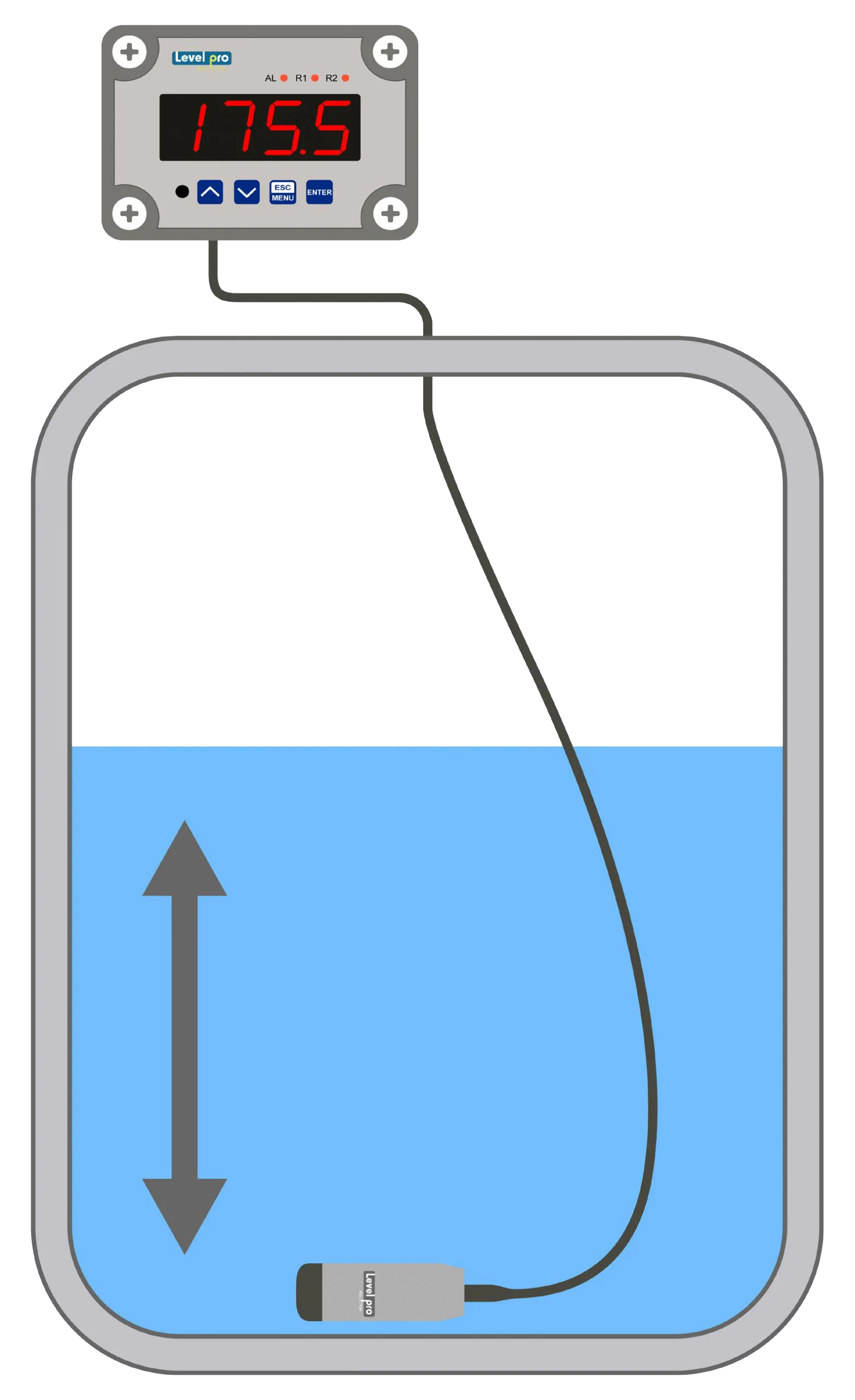

The weight of the liquid in a tank is used to calculate the level of submersible level sensors. Usually, the sensor is a body that must sink to the tank’s bottom. The circuit board that measures the weight or water column of the liquid above the submersible level sensor diaphragm is part of the sensor’s body.

The pressure that the liquid puts on the submersible level sensor, which is transformed into a 4-20 mA signal, serves as a gauge for the liquid’s weight. A common industrial signal called 4-20 mA is used to send data from sensors to control systems. It is a current-based signal that can travel great distances without suffering greatly from accuracy loss.

A control system or a display unit can read the submersible level sensor’s 4-20mA signal output. This signal can be used by the control system to operate other pieces of machinery or procedures, such as pumps, valves, or alarms. The liquid level in the tank can be seen on the display unit, which is helpful for troubleshooting and monitoring.

Submersible level sensors are a suitable choice for bulk chemicals because they don’t have any moving parts and don’t need programming. As a result, there is little chance of a mechanical failure and less maintenance is needed. Additionally, a variety of materials, including PVC, CPVC, PP, PVDF, and 316 stainless steel, which offers exceptional chemical resistance, are available for the Levelpro 100 series submersible level sensors. Additionally, they come in a variety of shapes and sizes to fit a range of applications.

On the other side, ultrasonic level sensors send out high-frequency sound waves that the liquid surface reflects back. The distance to the liquid surface and subsequently the level are determined by measuring the time it takes for the sound wave to go there and back. Foam, mist, condensation, and turbulence can all cause issues for ultrasonic sensors and reduce the measurement’s accuracy. These sensors need a clean path to the liquid surface and are sensitive to alignment.

Radar level sensors measure the amount of time it takes for a radar signal to travel to the liquid surface and return. They work on the basis of microwave radar. Additionally, they are delicate to alignment and have problems with foam, which can skew measurements. In general, they cost more than ultrasonic and underwater sensors.

In conclusion, submersible level sensors provide a dependable and precise liquid level measurement method, especially for bulk chemicals and hostile settings. They require less maintenance because they are simple to instal and don’t have any moving parts. On the other hand, foam, vapour, condensate, and turbulence can have an impact on ultrasonic and radar sensors, which can reduce measurement accuracy. Additionally, compared to radar and ultrasonic level sensors, submersible level sensors are less expensive.

Learn more about level sensors

Please contact us to discuss your application