Submersible Level Sensor Industry’s Most Reliable Tank Level Monitoring

Due to their long-term reliability , precision, and ease of installation, submersible level sensors are the preferred option for bulk chemical suppliers and are also widely utilized for remote tank level monitoring. They are designed to be completely submerged in the liquid, which enables them to measure the entire liquid level in a tank with no deadband. This implies they can give continuous and precise liquid level monitoring regardless of the tank’s shape or size. Submersible level sensors can detect a broad variety of liquids, including corrosive and viscous fluids, and are suited for use in severe situations.

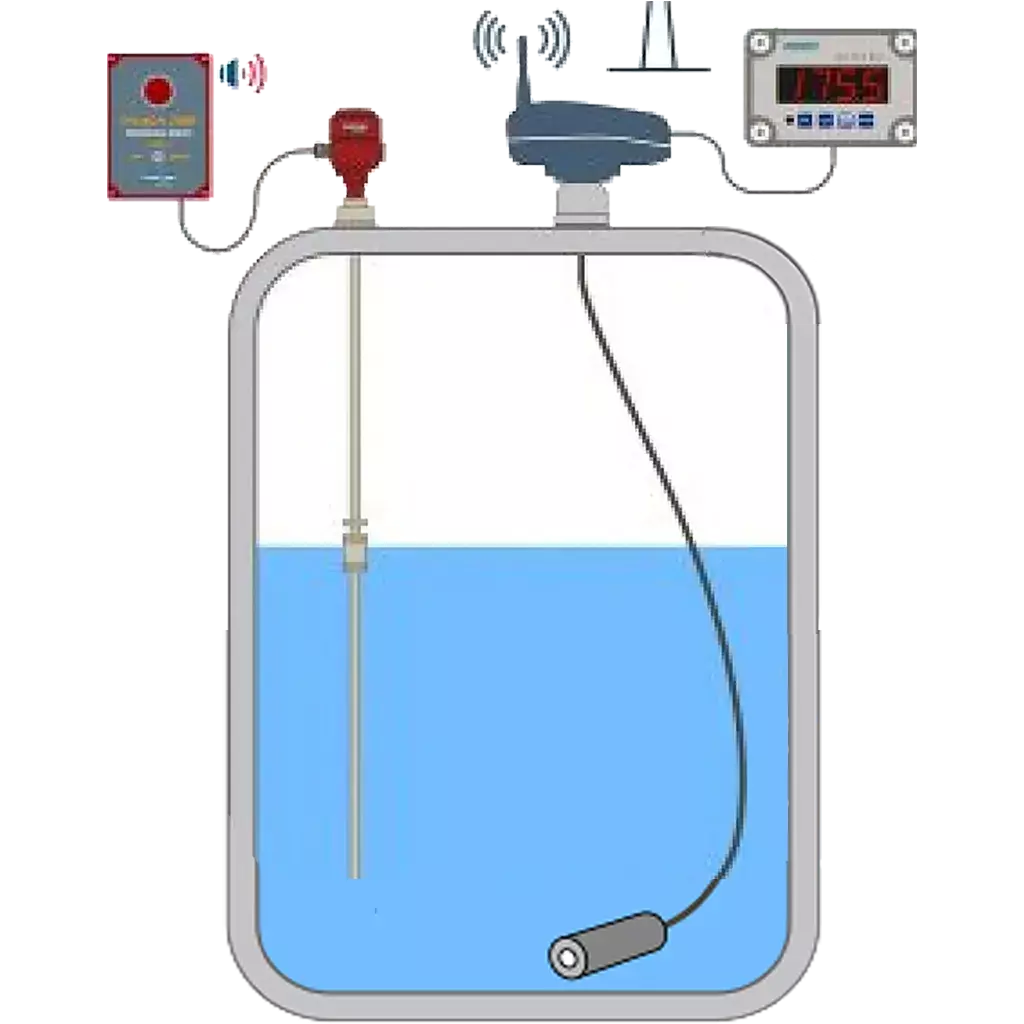

Submersible level sensors function by measuring the liquid’s weight in a tank. Typically, the sensor has a body that must sink to the bottom of the tank. The submersible level sensor body comprises of an internal circuit board that measures the weight or water column of the liquid above the sensor’s diaphragm.

The pressure exerted by the liquid on the submersible level sensor is transformed into a 4-20mA signal to measure the liquid’s density. The 4-20mA signal is an industry-standard signal used to send sensor data to control systems. It is a signal based on current that can be broadcast across great distances without considerable accuracy loss.

The submersible level sensor’s 4-20mA signal output can be interpreted by a control system or a display unit. This signal can be used by the control system to operate pumps, valves, and alarms, among other equipment and operations. The display device is capable of displaying the tank’s liquid level, which is useful for monitoring and troubleshooting.

Submersible level sensors are a suitable choice for bulk chemicals because they have no moving parts and do not require programming. This removes the possibility of mechanical failure and reduces required maintenance. The submersible Levelpro 100 series level sensors are also available in a number of chemically resistant materials, including PVC, CPVC, PP, PVDF, and 316 stainless steel. Additionally, they are available in a variety of sizes and configurations to accommodate varied applications.

In contrast, ultrasonic level sensors emit high-frequency sound waves that are reflected by the liquid surface. The time it takes for a sound wave to travel to the surface of a liquid and back is used to compute the distance to the surface and consequently the level. However, foam, mist, condensation, and turbulence can impair the accuracy of ultrasonic sensors, hence affecting the measurement. Additionally, these sensors are alignment-sensitive and require a clear path to the liquid surface.

Using the principle of microwave radar, radar level sensors measure the time required for a radar signal to travel to the liquid surface and return. Additionally, they are sensitive to alignment and have problems with foam, both of which can influence measurement accuracy. Typically, they are more expensive than ultrasonic and submerged sensors.

In conclusion, submersible level sensors offer a trustworthy and precise method for liquid level measurement, particularly in severe settings and for bulk chemicals. They are simple to instal and contain no moving parts, reducing the need for maintenance. In contrast, ultrasonic and radar sensors can be impacted by foam, mist, condensation, and turbulence, which can impact measurement accuracy. Moreover, submersible level sensors are more affordable than radar sensors and ultrasonic level sensors.

Learn more about level sensors

Please contact us to discuss your application