Bulk Chemical Level Switch

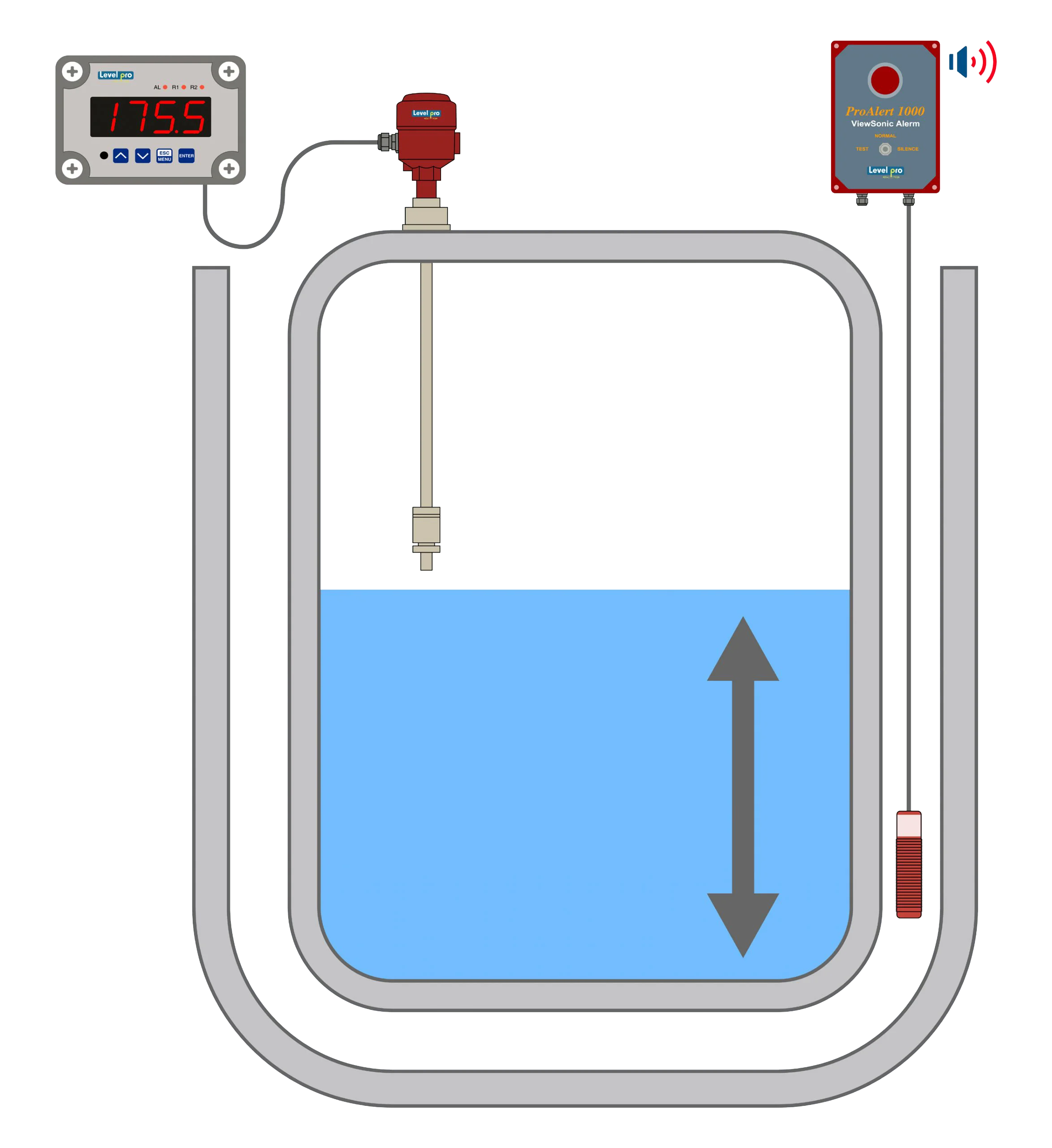

To keep track of the liquid level in a chemical tank, a chemical level switch is placed. There are several reasons why installing a chemical level switch in bulk chemical tanks is crucial. It primarily enables the monitoring and management of the tank’s liquid chemical level. This is essential for safety reasons because running out of chemicals or overfilling them might result in spills or other hazardous circumstances. By setting off an alarm or turning the flow of chemicals off automatically when specific levels are achieved, high chemical level and low chemical level switches can stop these situations from occurring.

Chemical level switches come in a variety of varieties, each with unique benefits and drawbacks. The float level switch is one popular variety. An object that is buoyant, like a float, and that rises or lowers in response to the level of the liquid is used in this kind of chemical level switch. The float is attached to a switch mechanism that, when the float reaches a specified level, opens a shut-off valve or sounds an alarm. Chemical level switches of the float type are easy to operate, affordable, and suitable for both high and low level alarms.

The vibration level switch is an additional kind of chemical level switch. This kind of switch employs a mechanical vibration sensor that senses the change in vibration brought on by the movement of the liquid to detect changes in the level of liquid. Industrial applications frequently use vibration level switches because they are typically more dependable and accurate than float level switches.

The capacitive level switch is a third variety of chemical level switch. This kind of switch detects changes in level by adjusting its capacitance, or capacity to hold electrical charge, in response to the presence of a liquid. When monitoring large concentrations of conductive liquids, capacitive level switches are especially helpful. They can pick up even minute differences in the liquid level since they are sensitive to changes in the level.

Other level switches, like ultrasonic, radar, and laser level switches, are also offered in addition to these varieties. Each of these varieties of chemical level switches has advantages and disadvantages of its own and is appropriate for a particular application.

Overall, maintaining secure and effective chemical handling and storage activities requires the use of chemical level switches. They offer a practical means of avoiding chemical overstocking and shortages, lowering the possibility of spills and other hazardous circumstances. Additionally, it is crucial to make sure that the chemical level switches are installed and maintained in accordance with the instructions to avoid any penalties given the growing rules for workplace safety.