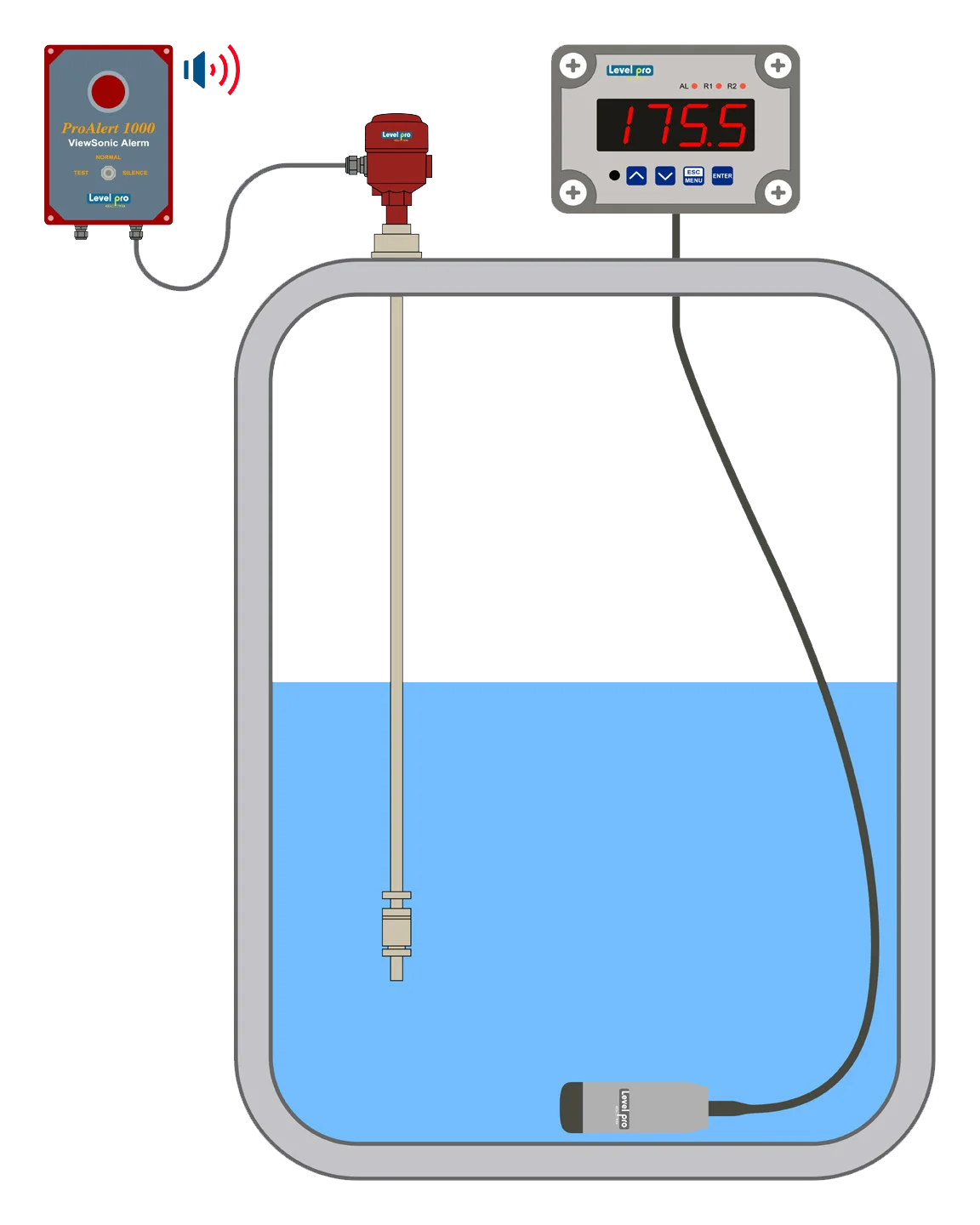

Submersible Tank Level Sensor vs. Ultrasonic Level Sensor

When it comes to detecting liquid levels in industrial and commercial applications, submersible level sensors and ultrasonic level sensors are both extremely common types of sensors to utilize. Every variety of sensor comes with its own set of benefits and drawbacks; which one is selected from the available options depends on the particular demands placed upon the sensor by the application.

The following are some of the benefits of submersible level sensors:

Durability: Because submersible level sensors are made to be submerged in liquid, they are an excellent choice for demanding situations and applications in which the sensor may be subjected to harsh chemicals or high temperatures. Typically, they are constructed out of materials that are resistant to corrosion and have the capacity to handle the pressure that comes with being submerged.

Easy installation: Submersible level sensors are easy to install since they only need a small hole to be drilled in the tank or container, and then the sensor merely needs to be inserted and connected to the control system. This installation process takes very little time and effort.

Submersible level sensors are typically more cost-effective than ultrasonic level sensors because of their lower price point. As a result, these sensors are a viable option for a wide variety of applications.

No Programming Necessary: Submersible tank level sensors don’t need any programming to work. The Icon 100 series submersible sensor features an integrated weight that keeps it positioned at the base of the tank.

The submersible tank level sensor does not contain any moving parts and is simply used to monitor head pressure.

Ultrasonic level sensors have the following disadvantages:

The following are some of the benefits of ultrasonic level sensors:

Non-contact measurement: Ultrasonic level sensors are able to determine the level of liquids without having to come into contact with the liquids themselves. Because of this, ultrasonic level sensors are suitable for applications in which the liquid being measured is either dangerous or difficult to access.

Ultrasonic level sensors are able to monitor even minute shifts in liquid level due to their high level of precision, which comes from the fact that they use sound waves to determine the level of a liquid rather than other methods.

Multiple measurement options: Because ultrasonic level sensors may be used to measure level as well as distance and volume, they are versatile and appropriate for a large variety of applications.

Long-range measurement: Because ultrasonic level sensors are able to monitor liquid level from a distance, they are ideal for determining the level of liquid in big tanks or containers that are difficult to access.

In conclusion, submersible level sensors are long-lasting, simple to set up, and affordable, whereas ultrasonic level sensors are contactless, accurate, adaptable, and appropriate for long-range measurement. The individual needs of the application, such as the environment, precision, and measuring range, will be taken into consideration while making the decision between the two different types of sensors.

Learn more about level sensors

Please contact us to discuss your application