When to Use A Submersible Tank Level Sensor vs. Ultrasonics

Submersible level sensors and ultrasonic level sensors are both commonly used for measuring liquid levels in industrial and commercial applications. Each type of sensor has its own advantages and disadvantages, and the choice between them will depend on the specific requirements of the application.

Advantages of submersible level sensors:

- Durability: Submersible level sensors are designed to be immersed in liquid, which makes them well-suited for harsh environments and applications where the sensor will be exposed to harsh chemicals or high temperatures. They are typically made of materials that are resistant to corrosion and can withstand the pressure of being submerged.

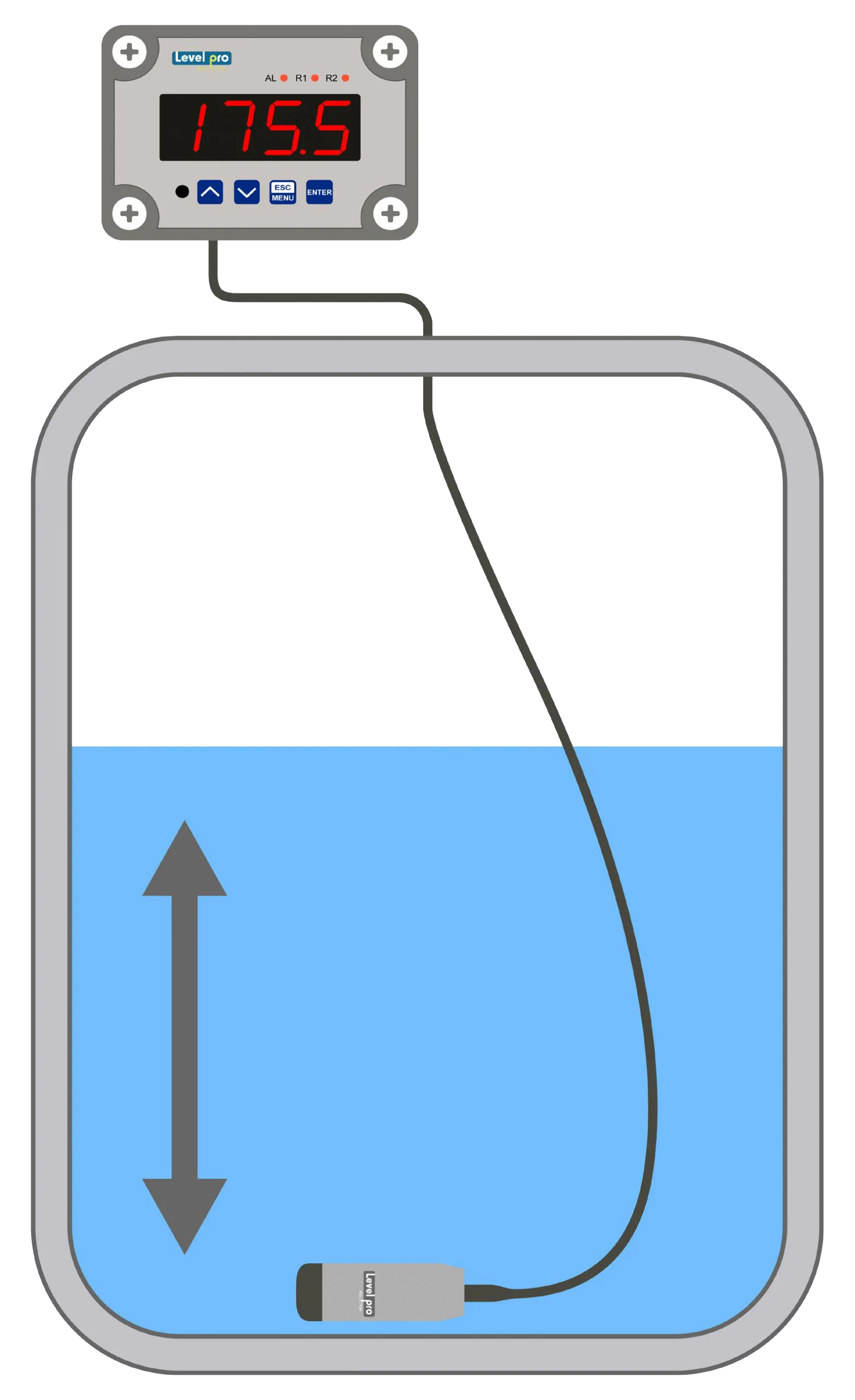

- Easy installation: Submersible level sensors are easy to install as they only require a small hole to be drilled in the tank or container, and then the sensor is simply inserted and connected to the control system.

- Cost-effective: Submersible level sensors are generally less expensive than ultrasonic level sensors, making them a cost-effective solution for many applications.

- No Programming: Submersible tank level sensors require no programming, the Icon 100 series submersible sensor has an integral weight that ensures the sensor sits at the bottom of the tank.

- No Moving Parts: The Submersible tank level sensor only measure head pressure

Disadvantages of ultrasonic level sensors:

- Constant Specific Gravity: Submersible tank levels sensors measure the liquid head pressure that exerts a force applied to the diaphragm. The specific gravity of the liquid must be constant

Advantages of ultrasonic level sensors:

- Non-contact measurement: Ultrasonic level sensors measure the level of liquids without coming into contact with them, which makes them suitable for applications where the liquid is hazardous or difficult to access.

- High accuracy: Ultrasonic level sensors use sound waves to measure the level of a liquid, which makes them highly accurate and able to measure even small changes in liquid level.

- Multiple measurement options: Ultrasonic level sensors can be used to measure level, distance, and volume, making them versatile and suitable for a wide range of applications.

- Long-range measurement: Ultrasonic level sensors can measure liquid level from a distance, which makes them useful for large tanks or containers where access is difficult.

Disadvantages of ultrasonic level sensors: Ultrasonic Tank Level Sensors are affected by foam, vapor, condensate and turbulence.

In summary, submersible level sensors are durable, easy to install and cost-effective, while ultrasonic level sensors are non-contact, accurate, versatile and suitable for long-range measurement. The choice between the two types of sensors will depend on the specific requirements of the application, such as the environment, accuracy, and measurement range.

Learn more about level sensors

Please contact us to discuss your application