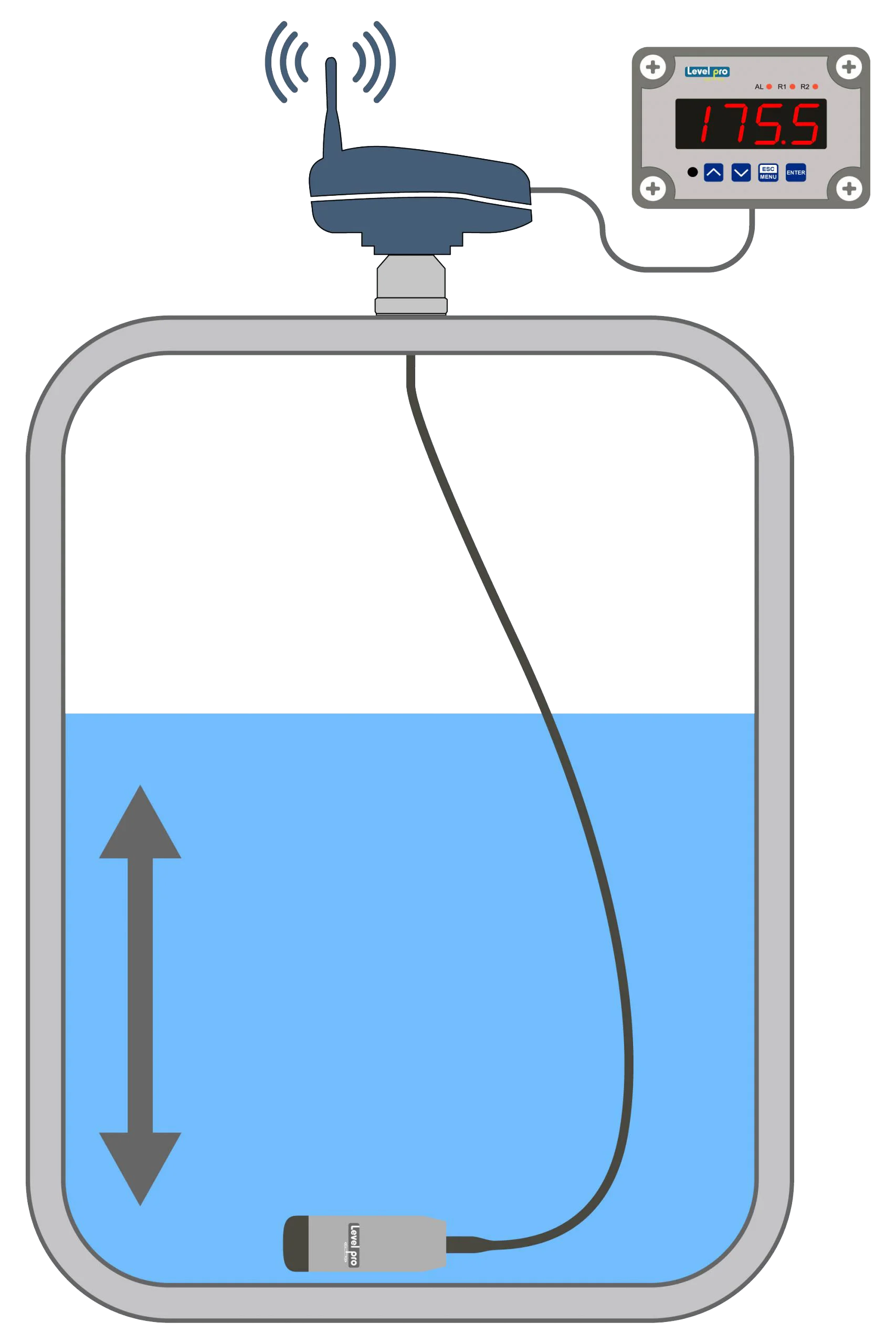

Submersible Level Sensor – Best Tank Level Sensor

Due to a number of factors, submersible tank level sensors are regarded as the best option for determining the level of liquids or bulk chemicals in tanks or other containers, including:

High accuracy: Submersible level sensors are frequently quite accurate and can give exact readings of the liquid or chemical level. This is so that they can remain unaffected by outside elements like temperature, pressure, vibration, or electromagnetic interference since they are in close touch with the liquid or chemical.

Durability: Submersible level sensors are often composed of sturdy materials like stainless steel because they are meant to resist the demanding conditions of being submerged in a liquid or chemical. This qualifies them for usage with corrosive or abrasive liquids and chemicals as well as in severe situations.

Versatility: Submersible level sensors can be utilized to gauge the concentration of a variety of liquids and substances, including caustic and abrasive substances. Additionally, they can be utilized in tanks of many sizes and designs, including cylinder-shaped and rectangular tanks.

Simple installation: Submersible level sensors don’t need any special tools or accessories to be fitted in tanks or other containers. There are numerous communication protocols that can be used to connect them to a control system, including 4-20 mA, HART, Modbus, Profibus, etc.

Cost-effective: Submersible level sensors are a cost-effective solution for many applications since they are frequently less expensive than other types of level sensors.

Maintenance-free: Submersible level sensors are easy to clean and maintain because the liquid they are measuring seals and protects them.

In order for submersible tank level sensors to function, the liquid or chemical being measured must be present. There are two ways they can function:

Contacting: These sensors make contact with the liquid and measure the liquid level using the buoyancy force of a float. The float floats up and down together with the liquid level, changing the resistance, capacitance, or other physical characteristics of the sensor as a result. The level of the liquid is then calculated using this change.

Non-Contacting: These sensors gauge the liquid level using ultrasound, radar, or other non-contact techniques. They produce sound or microwave signals, which are emitted into the liquid and returned by the surface. The distance to the liquid surface and subsequently the level are determined by measuring the time it takes for the signal to travel and return.

While submersible sensors are widely regarded as the best option, their suitability will ultimately depend on the properties of the liquid or chemical being monitored as well as the particular needs of the application. Always seek the advice of a professional to choose the optimal level sensor for your individual requirements.

Learn more about level sensors

Please contact us to discuss your application