Understanding Why Submersible Level Sensors Best Choice Bulk Chemicals

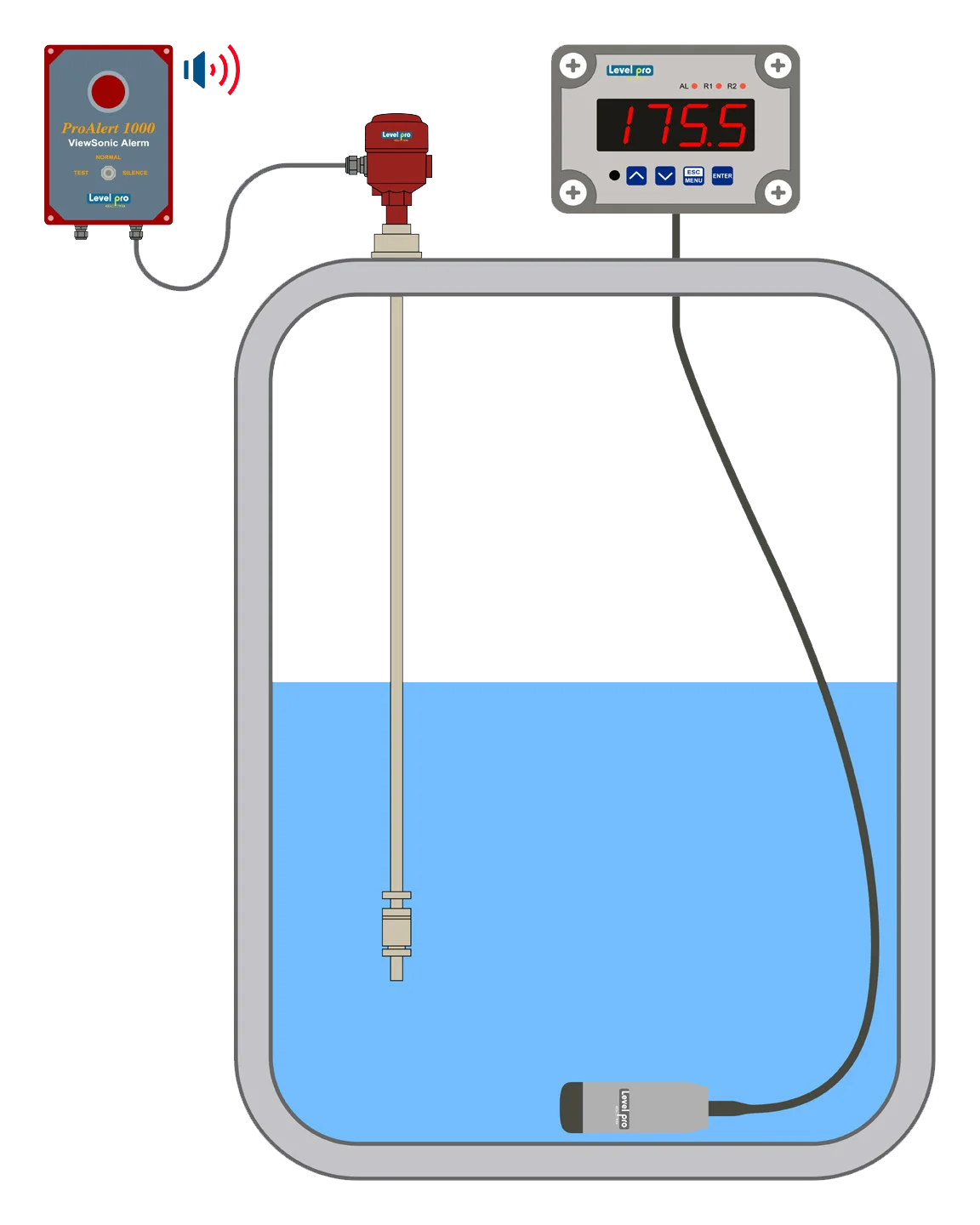

A level sensor that can be submerged in a liquid or bulk chemical is known as a submersible level sensor. Usually, the amount of liquids or chemicals in tanks or other containers is measured using these sensors. Using a submersible level sensor has the following advantages:

High accuracy: Submersible level sensors are frequently quite accurate and can give exact readings of the liquid or chemical level.

Durability: Submersible level sensors are often composed of sturdy materials like stainless steel because they are meant to resist the demanding conditions of being submerged in a liquid or chemical.

Versatility: Submersible level sensors can be utilized to gauge the concentration of a variety of liquids and substances, including caustic and abrasive substances.

Simple installation: Submersible level sensors don’t need any special tools or accessories to be fitted in tanks or other containers.

Cost-effective: Submersible level sensors are a cost-effective solution for many applications since they are frequently less expensive than other types of level sensors.

Submersible level sensors can work with a variety of communication protocols, including 4-20 mA, HART, Modbus, Profibus, etc., making it simple to integrate them into diverse control and monitoring systems.

Immunity to external interference: Pressure, temperature, vibration, and electromagnetic interference have no impact on submersible level sensors.

Simple upkeep: The sensor is easily cleaned and maintained because it is immersed in liquid and sealed.

The level of some types of bulk chemicals that are not corrosive or abrasive can also be measured using submersible level sensors, despite the fact that this is normally how they are used to monitor the level of liquids.

Learn more about level sensors

Please contact us to discuss your application