Why Submersible Level Sensors are your best choice for corrosive chemicals

Hydrostatic level sensors, also known as pressure sensors, work by measuring the pressure inside a tank or container and determining the level of the contents based on the pressure.

Here’s how they work:

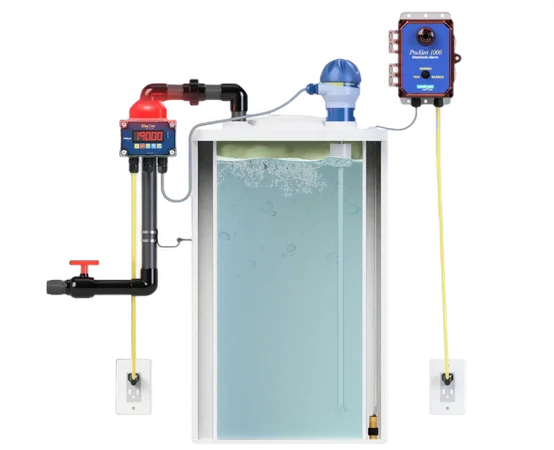

- The sensor is installed inside the tank or container, usually near the bottom.

- The sensor consists of a diaphragm or other flexible element that is connected to a pressure-sensitive element, such as a strain gauge.

- As the level of the contents in the tank increases, the pressure inside the tank increases as well. This pressure is transmitted to the diaphragm or flexible element, which moves in response to the pressure.

- The movement of the diaphragm or flexible element is then transmitted to the pressure-sensitive element, which generates an electrical signal proportional to the pressure.

- The electrical signal is then sent to a transmitter, which converts it into a form that can be read by a display or other monitoring device.

- The display or monitoring device shows the level of the contents in the tank based on the pressure readings from the hydrostatic level sensor.

Hydrostatic level sensors are generally accurate and reliable, and are commonly used for measuring the level of liquids, gases, and solids. They can be used in a variety of applications, including tanks, reservoirs, and wells. When selecting a level sensor for a tank, it’s important to consider the specific requirements of the application, including the type of tank, the location of the sensor, the sensitivity of the sensor, the ease of installation, compatibility with other equipment, and cost. It’s also a good idea to do research and read reviews from other users to get a sense of which sensors are the most reliable and effective.

Learn more about level sensors

Please contact us to discuss your application