LevelPro Brine Liquid Level Sensors from Icon Process Controls: Key Models and Features

Icon Process Controls’ LevelPro series offers advanced liquid level sensors tailored for brine and other corrosive applications. The LevelPro 100 Series submersible liquid level sensor, ProScan 3 80GHz radar liquid level sensor, and LevelPro Liquid Level Switches are each designed with specific features that make them well-suited for managing brine tanks and similar corrosive environments.

LevelPro 100 Series Submersible Liquid Level Sensor

The LevelPro 100 Series is a durable submersible sensor designed for accurate level measurements in brine and other corrosive liquids. This sensor offers several key features for reliable brine tank monitoring:

- Submersible Design for High-Corrosion Environments

Built to be fully submerged in liquid, the LevelPro 100 Series can handle challenging conditions in brine tanks. Its construction from corrosion-resistant materials ensures long-term reliability. Hence, minimizing the need for frequent replacements and reducing maintenance costs. - Accurate Real-Time Level Monitoring

The LevelPro 100 Series provides continuous, real-time data on tank levels. Thus, allowing operators to take action before levels reach unsafe limits. This accuracy is especially important for managing brine levels. Specifically, as it helps facilities avoid overflow and maintain a consistent brine supply. - Wireless Capabilities for Remote Monitoring

This model can be equipped with wireless connectivity, allowing operators to monitor brine tank levels remotely. For facilities with multiple tanks or those that rely on bulk brine deliveries, wireless monitoring saves time and reduces the need for manual inspections.

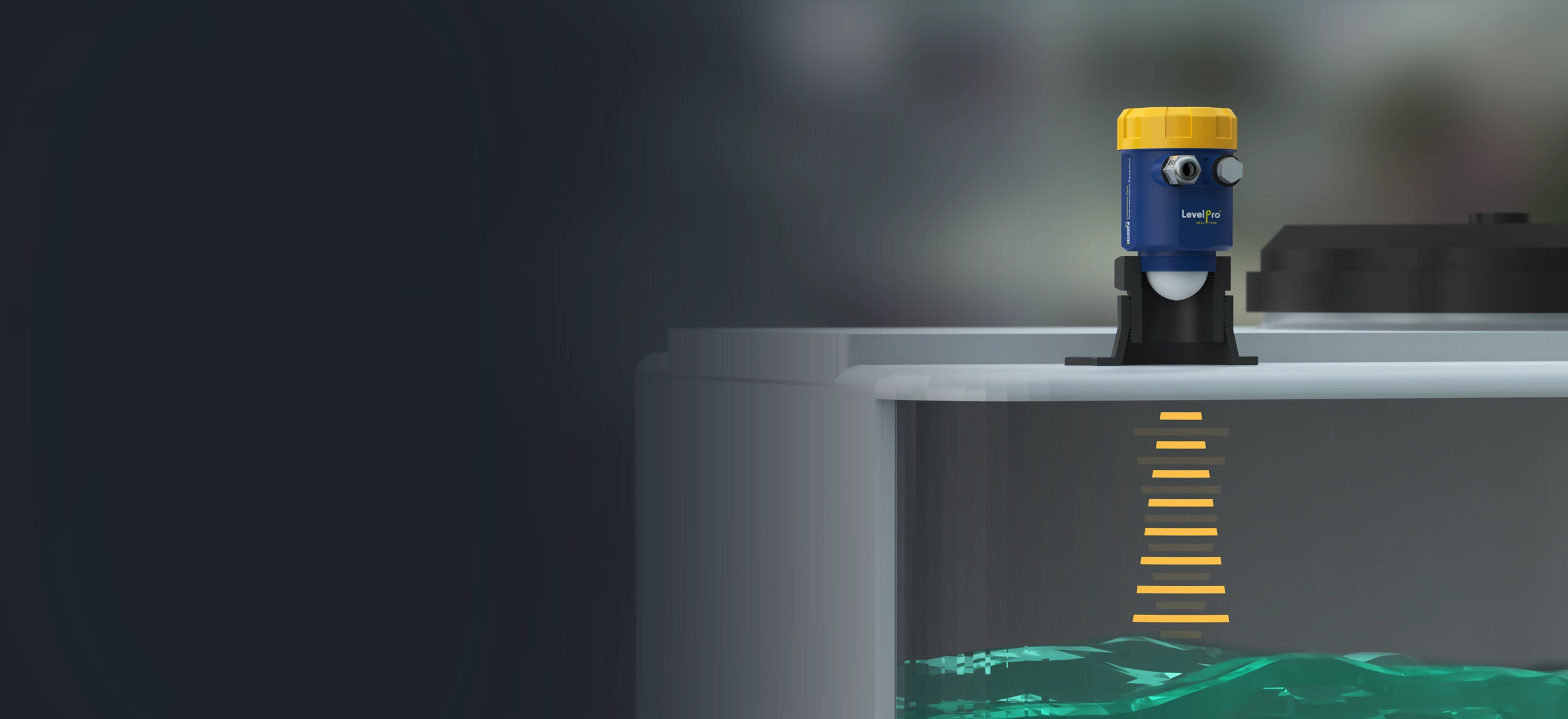

ProScan3 80G Radar Liquid Level Sensor

The ProScan 3 80GHz radar sensor offers a non-contact approach to level measurement, making it ideal for brine tanks where direct contact can accelerate wear and corrosion.

- Non-Contact Radar Technology for Reliable Measurement

Using radar waves, the ProScan 3 80GHz radar measures tank levels from a distance. Subsequently, preventing sensor exposure to corrosive brine. This non-contact technology reduces the risk of sensor degradation. Therefore, ensuring reliable performance over time. - Precision in Challenging Conditions

The ProScan3 80G is highly accurate even in conditions with temperature fluctuations or surface turbulence, which are common in brine tanks. Its precision ensures operators receive reliable data. Hence, helping them manage brine levels accurately and avoid costly overflows. - Wireless Data Transmission for Remote Access

With wireless connectivity, the ProScan3 80GHz allows operators to access tank level data from a central control room or even off-site. Wireless alerts for high or low levels ensure that operators can respond quickly to any issues. Indeed, keeping tank levels within safe ranges at all times.

LevelPro Liquid Level Switch

The LevelPro Liquid Level Switches offer reliable, high- and low-level switching for brine tanks. Consequentlty, providing dependable operation for a range of industrial applications.

- High-Corrosion Resistance for Long-Term Reliability

The LevelPro switch is constructed from corrosion-resistant materials. Thus, making it suitable for brine and other corrosive liquids. Additionally, this durability ensures consistent performance. Therefore, reducing the need for frequent replacements in challenging environments. - Wireless Monitoring and Remote Alerts

Integrated with wireless technology, this level switch provides operators with real-time alerts for high or low tank levels. Specifically, allowing them to respond promptly to changes. Wireless monitoring is invaluable for facilities managing bulk brine deliveries or those with tanks located in remote areas. - Reliable Switching for Brine and Water Applications

Designed for brine tanks, the LevelPro switch also performs well in water applications. Absolutely, making it versatile for use in various industrial and commercial settings.

The Importance of Wireless Monitoring for Brine Tanks

In industries where brine is used, tanks are often large, remotely located, or present safety risks due to the corrosive nature of the contents. Wireless monitoring for brine tanks addresses these challenges by enabling real-time, remote access to tank data, minimizing the need for manual checks. Here’s why wireless level monitoring is essential for brine tanks:

- Enhanced Safety and Reduced Worker Exposure

- Wireless monitoring allows operators to oversee brine tank levels from a safe distance, reducing the risk of exposure to corrosive chemicals. Moreover, this added layer of safety is invaluable, especially for tanks in isolated or hazardous locations.

- Wireless alerts enable rapid response to potential issues, allowing facilities to address problems before they escalate and become safety hazards.

- Improved Operational Efficiency and Cost Management

- Real-time wireless monitoring provides facilities with immediate access to tank levels. Thus, simplifying inventory management and allowing for timely bulk brine deliveries. This improves logistics, minimizes downtime, and reduces labor costs associated with manual level checks.

- By ensuring that tanks are always maintained at optimal levels, facilities can avoid over-purchasing or running out of brine, leading to cost savings and improved resource management.

- Enhanced Data Collection for Compliance and Reporting

- Wireless level sensors provide continuous, reliable data on tank levels, which can be recorded for compliance with OSHA and environmental regulations. This data helps facilities demonstrate their commitment to safety and regulatory standards.

- Data from wireless sensors can also be used for trend analysis, helping facilities optimize brine usage and manage inventory more efficiently.

Real-World Insights: Industry Professionals on the Value of Reliable Brine Level Sensors

Here are some real-world perspectives from professionals who rely on LevelPro liquid level sensors for managing brine tanks and ensuring efficient, safe operations:

Operations Manager, Water Treatment Facility

“The LevelPro 100 Series has been critical for our brine storage. The sensor’s corrosion-resistant design means it’s built to last, and wireless monitoring has allowed us to check levels remotely, reducing manual labor and improving safety for our team. We’ve had fewer overflows, which has made our operations more efficient and environmentally responsible.”

Plant Engineer, Food Manufacturing Facility

“We use the ProScan3 80G radar sensor for our brine tanks. The non-contact design is ideal because it doesn’t degrade in the corrosive environment, and the wireless feature means I can monitor levels from anywhere. It’s saved us time and helped us avoid costly overflows, which is crucial when managing large volumes of brine.”

Environmental Compliance Officer, Chemical Plant

“Wireless level sensors have made it easier for us to comply with OSHA and EPA standards. We can track brine levels accurately and respond to issues quickly, keeping us within regulatory limits. The LevelPro sensors have proven to be reliable and a good investment for our compliance and safety programs.”

These insights illustrate how LevelPro sensors help facilities optimize brine tank monitoring, reduce safety risks, and achieve compliance with industry standards.

Best Practices for Implementing Liquid Level Sensors in Brine Tanks

To maximize the effectiveness of brine level sensors, consider these best practices for implementation and maintenance:

- Prioritize High-Corrosion Tanks for Sensor Installation

Focus on installing sensors in tanks that store high volumes of brine or other corrosive substances, as these tanks benefit most from real-time monitoring and protection. - Schedule Regular Calibration and Maintenance

Even reliable sensors require periodic calibration and maintenance to ensure ongoing accuracy. Regular checks help prevent measurement drift and ensure sensors continue to perform optimally in corrosive environments. - Integrate with a Central Monitoring System

Connect wireless level sensors to a central system for streamlined monitoring. This integration allows operators to oversee multiple tanks from a single interface, simplifying data collection and improving response times. - Train Employees on Remote Monitoring Protocols

Provide training on how to interpret remote data and respond to alerts. Establishing clear procedures for handling high- or low-level alarms ensures that issues are addressed promptly to prevent spills, overflows, or equipment damage. - Leverage Data for Inventory and Usage Optimization

Use data from wireless sensors to track brine usage patterns, forecast needs, and optimize ordering schedules. This approach improves inventory management, minimizes waste, and ensures that facilities have brine readily available when needed.

Building a Community Around Brine Tank Monitoring and Safety

Creating a knowledgeable user community around brine tank monitoring helps raise awareness of best practices and promotes the benefits of reliable level sensors. Here are ways to build an informed and engaged user base:

- Share Case Studies and Success Stories

Publish case studies that showcase how facilities have benefited from LevelPro sensors. These real-world examples provide insights into how brine tank monitoring improves safety, efficiency, and compliance. - Encourage User-Generated Content and Testimonials

User-generated content, such as reviews and testimonials, allows customers to share their experiences, providing valuable feedback for others considering level sensors. - Host Webinars and Q&A Sessions

Organize webinars with experts in tank monitoring and safety. These sessions provide users with the opportunity to ask questions and learn from industry leaders. - Regularly Publish Educational Guides and Articles

Consistent content on topics like sensor maintenance, compliance, and wireless monitoring keeps users engaged and provides them with a reliable knowledge base.

By fostering a community focused on safety and best practices, companies can enhance awareness of brine tank monitoring and promote the use of reliable liquid level sensors in industrial settings.

Conclusion

For industries that handle brine, reliable liquid level sensors are a necessity. Icon Process Controls’ LevelPro 100 Series submersible sensor, ProScan 3 80GHz radar sensor, and LevelPro Liquid Level Switches offer dependable solutions for tank monitoring in corrosive and high-risk environments. Additionally, these sensors support OSHA and EPA compliance, enhance operational efficiency, and protect against spills and overflows.

Wireless monitoring capabilities further improve convenience and safety, allowing facilities to monitor brine tanks remotely and respond promptly to critical alerts. For businesses managing brine or other corrosive chemicals, LevelPro’s sensors are an essential investment in safety and efficiency.

By building an engaged user community around these solutions, companies can share insights, promote best practices, and contribute to a safer, more efficient industry.