All About Water Treatment Liquid Level Sensors

Water treatment liquid level sensors are vital for ensuring efficient and safe operations in water and wastewater treatment facilities. These sensors monitor liquid levels in tanks, reservoirs, and treatment processes. Therefore, helping to prevent overflows, leaks, and operational inefficiencies. Furthermore, accurate level monitoring is essential for maintaining water quality. Thus, optimizing chemical usage, and adhering to strict environmental regulations.

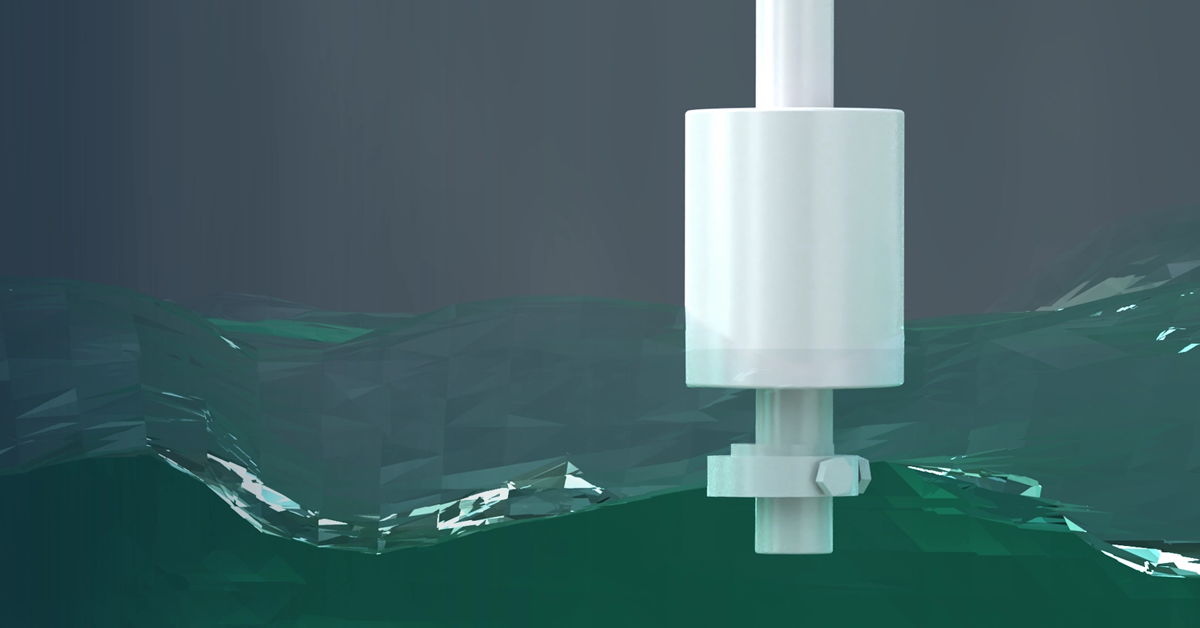

In water and wastewater treatment, liquid level sensors support processes like sedimentation, filtration, and chemical dosing. However, the sensors must withstand challenging environments, including exposure to corrosive chemicals, fluctuating temperatures, and varying liquid compositions. Consequently, advanced materials like PVC, PP, and PVDF ensure durability and resistance to harsh conditions.

Icon Process Controls specializes in cutting-edge water treatment liquid level sensors. Moreover, with features like wireless connectivity, real-time monitoring, and robust construction, these sensors meet the unique demands of modern treatment facilities. Consequently, this blog explores everything about these indispensable tools, from their types to real-world applications.

Understanding Water Treatment Liquid Level Sensors

Water treatment liquid level sensors measure and monitor liquid levels in tanks, basins, and reservoirs. Ultimately, these sensors ensure the precise handling of water and chemicals used in treatment processes. Hence, their reliable operation prevents spills, optimizes resource usage, and supports process automation.

Why Accurate Liquid Level Monitoring Matters

Accurate liquid level monitoring prevents costly overflows and ensures proper chemical dosing in treatment processes. It optimizes water usage and reduces operational waste. Maintaining precise levels protects equipment, safeguards water quality, and supports compliance with environmental regulations.

Icon Process Controls: A Trusted Name in Level Sensing Technology

Icon Process Controls leads the industry with advanced liquid level sensors designed for water and wastewater applications. Their sensors are crafted from corrosion-resistant materials like PP, PVDF, and PTFE. Icon’s technology ensures high precision, reliability, and durability even in challenging conditions.

Types of Water Treatment Liquid Level Sensors from Icon Process Controls

Submersible sensors measure continuous levels in basins and tanks. They are ideal for turbulent or foam-covered liquids.

Radar sensors provide non-contact measurement, making them suitable for corrosive or hazardous liquids. They ensure accuracy and safety.

Float sensors are reliable and cost-effective for point-level detection. They work well in straightforward water applications.

Ultrasonic sensors use sound waves to measure liquid levels. They are versatile and effective across diverse treatment systems.

Key Features of Icon’s Water Treatment Liquid Level Sensors

- Corrosion Resistance: Built with materials that withstand harsh chemicals.

- High Accuracy: Deliver precise readings for optimal process control.

- Durability: Designed to endure harsh water treatment environments.

- Wireless Integration: Enable remote monitoring and real-time alerts.

- Easy Installation: Reduce setup time and minimize operational disruptions.

Applications of Liquid Level Sensors in Water and Wastewater Treatment

- Sedimentation Tanks: Monitor sludge and water levels for effective separation.

- Chemical Dosing Systems: Ensure accurate levels for proper chemical application.

- Reservoir Management: Maintain consistent water levels to meet demand.

- Filtration Processes: Prevent overflows and optimize filter efficiency.

The Role of Wireless Technology in Water Treatment

Wireless technology streamlines water treatment operations by offering remote monitoring and real-time data access. It reduces installation costs by eliminating extensive wiring. Wireless sensors allow treatment plants to scale systems efficiently, ensuring adaptability for future needs.

Supporting Worker Safety and Compliance Standards

Water treatment liquid level sensors enhance safety by minimizing risks of spills and chemical exposure. They help facilities meet OSHA standards, ensuring worker protection and regulatory compliance.

Protecting the Environment with Reliable Sensors

Accurate level sensors prevent overflows that could lead to environmental contamination. They ensure treatment plants adhere to EPA regulations and promote sustainable practices by optimizing resource usage.

Real-World Testimonials: How Sensors Transform Operations

John D., Facility Manager:

“Icon’s submersible sensors ensure our sedimentation tanks remain at optimal levels. Real-time alerts prevent downtime and improve efficiency.”

Sarah L., Compliance Officer:

“Using Icon’s radar sensors has streamlined our chemical dosing system. Their accuracy and reliability keep us compliant with EPA standards.”

Mike T., Engineer:

“The wireless integration of Icon’s sensors saved us installation costs and made remote monitoring a seamless experience.”

Choosing the Right Water Treatment Liquid Level Sensor

Consider these factors when selecting a sensor:

- Liquid Composition: Choose sensors with materials compatible with the chemicals in use.

- Measurement Needs: Determine whether continuous or point-level monitoring suits your application.

- Environment: Evaluate factors like temperature, turbulence, and the presence of foam.

- Installation Requirements: Opt for wireless options for remote or hard-to-access locations.

Frequently Asked Questions

Why are water treatment liquid level sensors important?

They ensure precise monitoring, prevent overflows, and optimize chemical dosing for efficient and safe treatment processes.

What makes Icon’s sensors ideal for water treatment?

Icon’s sensors feature corrosion-resistant materials, high accuracy, and wireless capabilities tailored for demanding treatment environments.

Are Icon’s sensors easy to integrate?

Yes, Icon’s sensors are designed for seamless integration with existing monitoring systems.

Conclusion

Water treatment liquid level sensors are critical for maintaining efficient, safe, and compliant operations. Icon Process Controls offers innovative solutions tailored to the unique demands of water and wastewater treatment facilities. From submersible to wireless sensors, Icon’s range ensures durability, precision, and adaptability for diverse applications.

Optimize your water treatment operations with Icon Process Controls’ advanced liquid level sensors. Explore our website to find the perfect solution for your needs, or contact our team today for expert advice tailored to your facility.