Best Bulk Chemical Level Sensors: Ensuring Safety and Efficiency with Icon Process Controls’ LevelPro Series

Managing bulk chemical storage requires precise, reliable, and durable chemical level sensors to ensure safety, optimize operations, and maintain compliance. Icon Process Controls’ LevelPro series, including the LevelPro 100 Series submersible sensor and the ProScan3 80G radar sensor, meets these demands with advanced technology and robust designs. This blog highlights why liquid level sensors are essential, explores LevelPro features, and offers actionable insights for industrial applications.

The Role of Liquid Level Sensors in Bulk Chemical Storage

Accurate liquid level sensors are vital for facilities handling bulk chemicals. Here’s how they contribute to safety, efficiency, and compliance:

1. Enhancing Safety and Mitigating Risks

Bulk chemical storage involves risks like spills, overflows, and leaks. Level sensors enable early detection, protecting workers and preventing environmental damage. Durable sensors like those in the LevelPro series withstand corrosive environments, ensuring accurate monitoring even in challenging conditions.

2. Supporting Compliance with OSHA and EPA Standards

Strict regulatory standards require robust safety measures in chemical storage. Level sensors help maintain precise records, ensuring compliance and avoiding fines, legal issues, or reputational harm.

3. Boosting Operational Efficiency

By automating level monitoring, sensors reduce manual intervention and errors. Real-time data streamlines inventory management, prevents overordering, and optimizes chemical deliveries.

4. Resilience in Corrosive Environments

LevelPro sensors are designed for high-risk environments where corrosion can degrade standard equipment. They maintain accuracy and reliability when handling harsh chemicals.

Key Features of Icon’s LevelPro Series

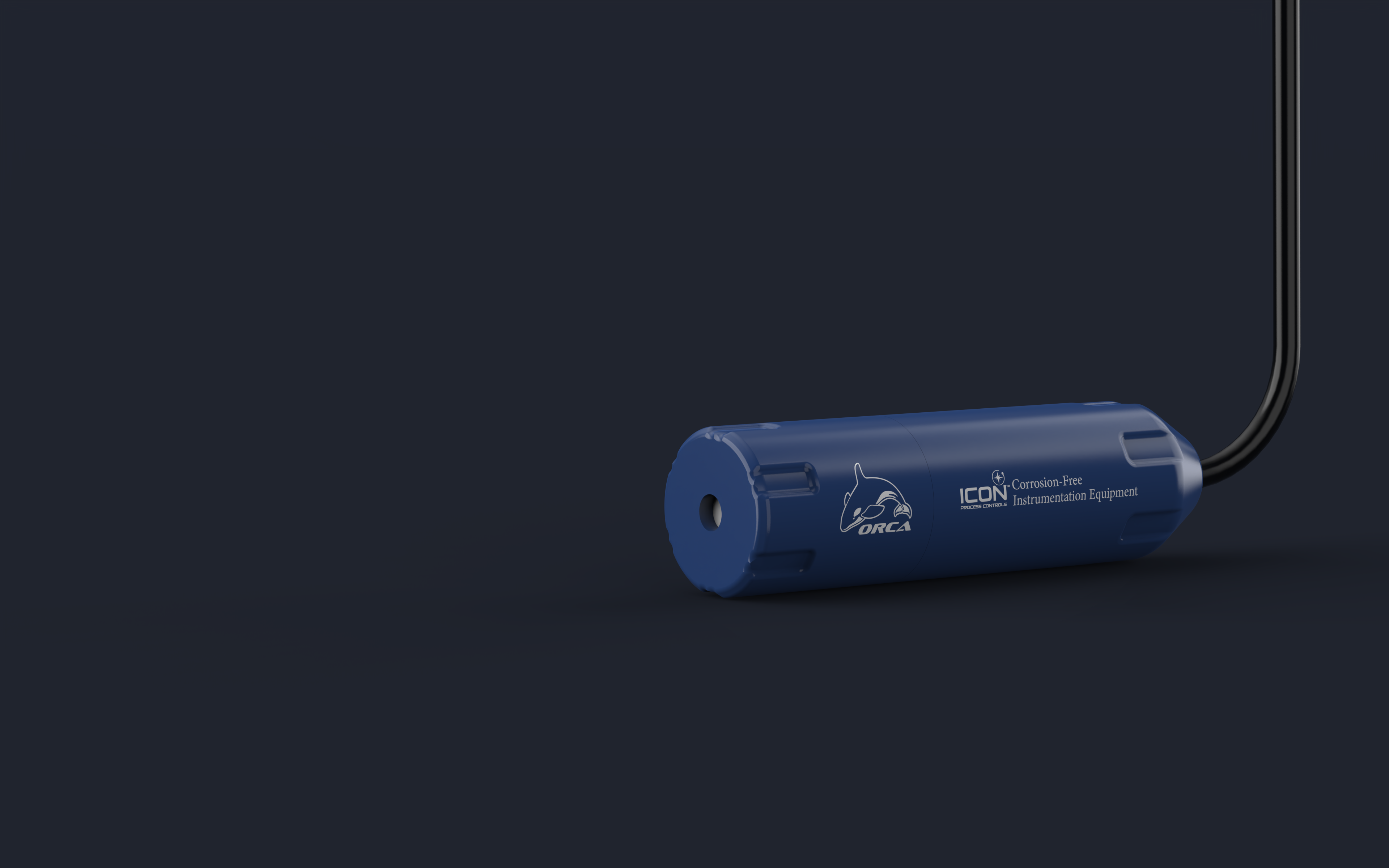

LevelPro 100 Series Submersible Level Sensor

- Fully submersible design for reliable use in large chemical tanks.

- Made with corrosion-resistant materials for durability.

- Real-time monitoring with instant alerts for high- or low-level alarms.

ProScan3 80G Radar Level Sensor

- Non-contact radar technology for hazardous or corrosive chemicals.

- High precision even in turbulent or extreme conditions.

- Built to handle high temperatures and pressures.

Insights from Industry Professionals

Facility Manager:

“The LevelPro 100 Series has been incredibly reliable, even in our most demanding tanks, reducing risks and improving efficiency.”

Compliance Officer:

“LevelPro sensors have streamlined our compliance efforts, ensuring accurate data and preventing environmental hazards.”

Best Practices for Sensor Implementation

- Prioritize High-Risk Tanks: Install sensors in critical areas first.

- Schedule Maintenance: Regular calibration ensures optimal performance.

- Integrate Monitoring Systems: Centralized tracking improves operational control.

- Train Staff: Employees must respond quickly to sensor alerts.

Conclusion

Icon Process Controls’ LevelPro series chemical level sensor offers robust, precise, and durable solutions for bulk chemical applications. From enhancing safety to ensuring compliance and efficiency, LevelPro sensors are essential tools for modern chemical storage facilities.

Learn how LevelPro sensors can transform your operations, improve safety, and support environmental responsibility. Contact Icon Process Controls for tailored solutions!