Best Chemical Liquid Level Sensors: Ensuring Safety and Efficiency in Industrial Applications

In industries handling hazardous chemicals, precise monitoring of liquid levels is paramount. The integration of advanced liquid level sensors not only enhances operational efficiency but also ensures compliance with safety and environmental regulations. Icon Process Controls stands at the forefront, offering state-of-the-art chemical liquid level sensors designed to meet the rigorous demands of modern industries.

Submersible Liquid Level Sensors

Radar Liquid Level Sensors

Ultrasonic Liquid Level Sensors

Float Liquid Level Sensors

Liquid Level Switches

Table of Contents

1 – Understanding Chemical Liquid Level Sensors

2 – Importance of Accurate Liquid Level Monitoring

3 – Icon Process Controls: A Leader in Liquid Level Sensing Technology

4 – Key Features of Icon’s Chemical Liquid Level Sensors

5 – Types of Liquid Level Sensors Offered by Icon Process Controls

6 – Applications Across Various Industries

7 – The Role of Wireless Technology in Liquid Level Sensing

8 – Ensuring Occupational Safety and Health Compliance

9 – Adhering to Environmental Protection Standards

10 – User Experiences: Real-World Benefits

11 – Selecting the Right Chemical Liquid Level Sensor

Frequently Asked Questions

Understanding Chemical Liquid Level Sensors

Chemical liquid level sensors are devices engineered to detect and measure the levels of liquids within industrial tanks, vessels, or containers. They play a crucial role in monitoring the presence, absence, or precise quantity of liquids, ensuring optimal process control and safety.

Importance of Accurate Liquid Level Monitoring

Accurate liquid level monitoring is vital for several reasons:

- Safety: Prevents overflows, leaks, and potential chemical spills that could harm personnel and the environment.

- Efficiency: Ensures optimal use of resources, reducing waste and operational costs.

- Regulatory Compliance: Helps industries adhere to safety and environmental regulations, avoiding legal penalties.

Icon Process Controls: A Leader in Liquid Level Sensing Technology

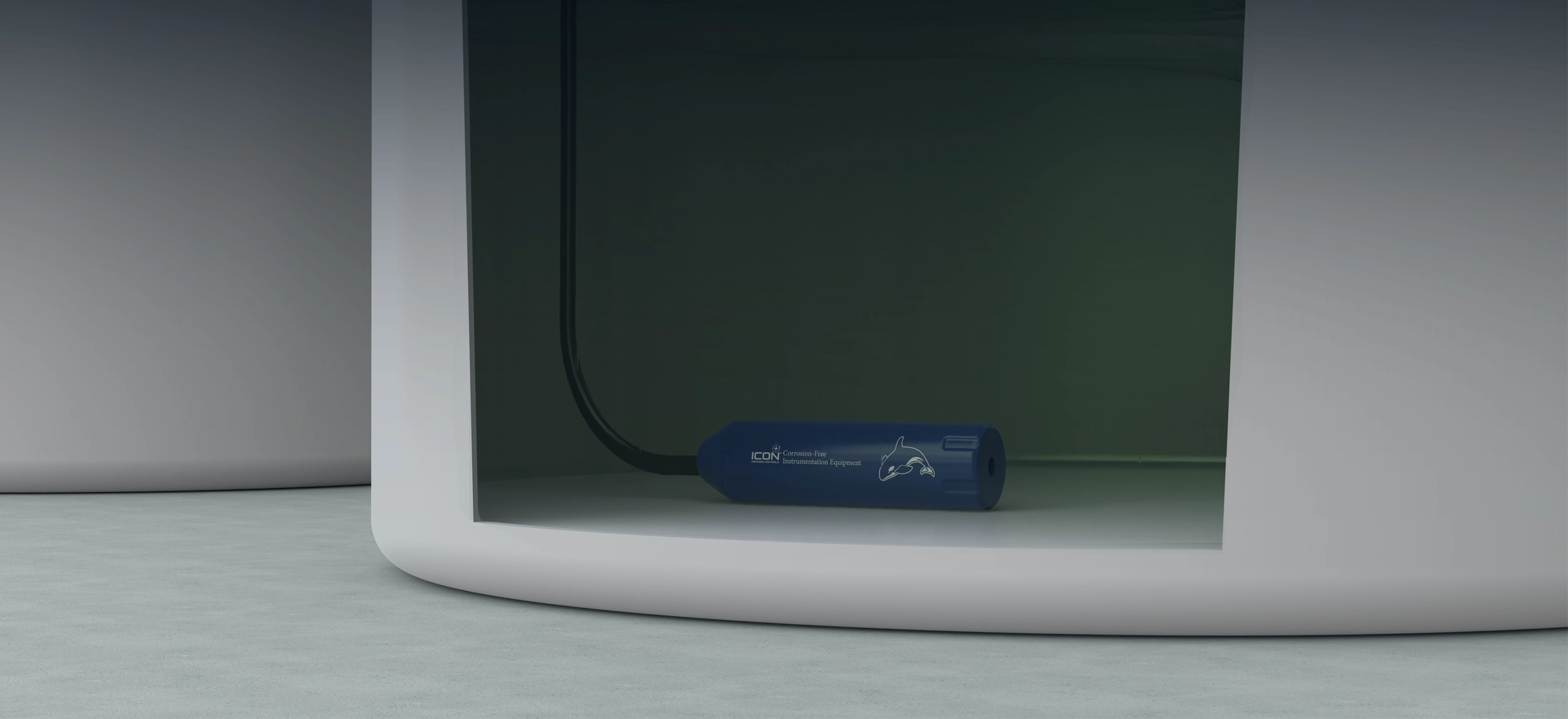

Icon Process Controls specializes in providing high-quality, corrosion-resistant industrial instrumentation. Their range of chemical liquid level sensors is designed to withstand harsh environments, ensuring durability and reliability in critical applications.

Key Features of Icon’s Chemical Liquid Level Sensors

Icon’s chemical liquid level sensors are distinguished by:

- Corrosion Resistance: Constructed from materials like PVC, PP, PVDF, and PTFE Teflon®, they resist aggressive chemicals.

- High Accuracy: Provide precise measurements, essential for maintaining process control and safety.

- Durability: Built to withstand harsh industrial conditions, ensuring long-term reliability.

- Minimal Maintenance: Designed for easy installation and low upkeep, reducing operational downtime.

Source: LevelPro 100 Series Liquid Level Sensor – ICON Process Controls

Types of Liquid Level Sensors Offered by Icon Process Controls

Icon Process Controls offers a diverse range of liquid level sensors to cater to various industrial needs:

- Submersible Level Sensors: Ideal for continuous level measurement in tanks, unaffected by foam, vapor, or turbulence.

- Radar Level Sensors: Provide non-contact measurement, suitable for corrosive or hazardous liquids.

- Ultrasonic Level Sensors: Use sound waves for measurement, effective in various applications.

- Float Level Sensors: Simple and reliable, used for point level detection.

Source: Liquid Level Sensors | Transmitters – ICON Process Controls

Applications Across Various Industries

Icon’s chemical liquid level sensors find applications in multiple industries:

- Chemical Processing: Monitoring storage tanks and reactors to prevent overflows and leaks.

- Water Treatment: Ensuring proper levels in treatment processes to maintain water quality.

- Oil and Gas: Managing storage and processing of hydrocarbons safely.

- Food and Beverage: Maintaining precise levels in production to ensure product quality.

The Role of Wireless Technology in Liquid Level Sensing

The integration of wireless technology in liquid level sensors offers significant advantages:

- Remote Monitoring: Allows real-time data access from any location, enhancing decision-making.

- Reduced Installation Costs: Eliminates the need for extensive wiring, simplifying setup.

- Scalability: Easily expand monitoring systems without significant infrastructure changes.

- Enhanced Safety: Immediate alerts for abnormal conditions, allowing prompt response.

Implementing wireless chemical liquid level sensors is crucial for:

- Preventing Hazardous Exposures: Early detection of leaks or spills protects workers from harmful substances.

- Maintaining Safe Work Environments: Continuous monitoring ensures adherence to safety protocols.

- Meeting Regulatory Standards: Compliance with OSHA and other safety regulations is facilitated through accurate monitoring.

Ensuring Occupational Safety and Health Compliance

Adhering to Occupational Safety and Health Administration (OSHA) standards is essential for industrial operations. Icon’s chemical liquid level sensors assist in:

- Preventing Accidents: By providing accurate level measurements, they help avoid overflows and spills.

- Protecting Workers: Ensuring safe handling and storage of hazardous chemicals.

- Maintaining Compliance: Meeting OSHA requirements for chemical storage and handling.

Source: Chemical Hazards and Toxic Substances – Standards | OSHA.gov

Adhering to Environmental Protection Standards

Environmental protection is a critical concern in industrial operations. Icon’s sensors contribute by:

- Preventing Environmental Contamination: Early detection of leaks prevents harmful chemicals from polluting soil and water.

- Ensuring Regulatory Compliance: Helping industries meet environmental regulations and avoid penalties.

- Promoting Sustainable Practices: Encouraging responsible management of chemical resources.

*Source: [Chemical Storage Safety OSHA Requirements – SafetyInfo](https://www.safetyinfo.com/safe-

User Experiences: Real-World Benefits

John M., Operations Manager:

“Switching to Icon’s wireless chemical liquid level sensors has been a game-changer. The real-time monitoring capability saves us hours of manual checks, and the early alerts have prevented potential spills.”

Sarah L., Environmental Compliance Officer:

“The durability of these sensors under harsh conditions is unmatched. They’ve ensured we maintain compliance with EPA standards, and the installation process was seamless.”

David R., Plant Engineer:

“The scalability and cost savings from not needing extensive wiring were significant for our operations. These sensors are worth the investment.”

Selecting the Right Chemical Liquid Level Sensor

When choosing a liquid level sensor, consider the following factors:

- Chemical Compatibility: Ensure the sensor materials can withstand the specific chemicals in your application.

- Measurement Type: Decide between continuous monitoring or point level detection based on your needs.

- Environmental Conditions: Consider factors like temperature, pressure, and corrosive environments.

- Connectivity Needs: Wireless sensors are ideal for remote or expansive facilities.

- Compliance Requirements: Ensure the sensor meets OSHA and EPA standards for chemical handling and storage.

Why are wireless chemical liquid level sensors essential?

Wireless sensors provide real-time monitoring, reduce installation costs, and offer enhanced safety through immediate alerts.

What industries benefit most from Icon’s chemical liquid level sensors?

Industries like chemical processing, water treatment, oil and gas, and food and beverage find these sensors invaluable.

Can Icon’s sensors handle corrosive chemicals?

Yes, Icon’s sensors are made with corrosion-resistant materials like PVDF and Teflon®, ensuring long-term reliability.

How do these sensors promote environmental protection?

They detect leaks early, preventing environmental contamination and helping industries adhere to EPA standards.

Are Icon’s sensors easy to install?

Absolutely. Icon designs their sensors for quick and hassle-free installation, especially wireless models.

What is the lifespan of these sensors?

With proper maintenance, Icon’s sensors are designed to provide years of reliable service.

Conclusion

Icon Process Controls delivers some of the best chemical liquid level sensors in the market, combining durability, precision, and advanced wireless technology. These sensors not only enhance operational efficiency but also ensure compliance with OSHA and environmental protection standards. Whether you’re managing a chemical plant or overseeing water treatment, investing in high-quality liquid level sensors is essential for safety, sustainability, and cost-effectiveness.