Best Way: Tank Level Monitoring

The process of telemetry remote tank monitoring involves employing wireless technology to track the liquid and chemical levels in tanks from a distance. Tanks that carry dangerous substances or chemicals or are situated in hard-to-reach locations can both benefit from this procedure.

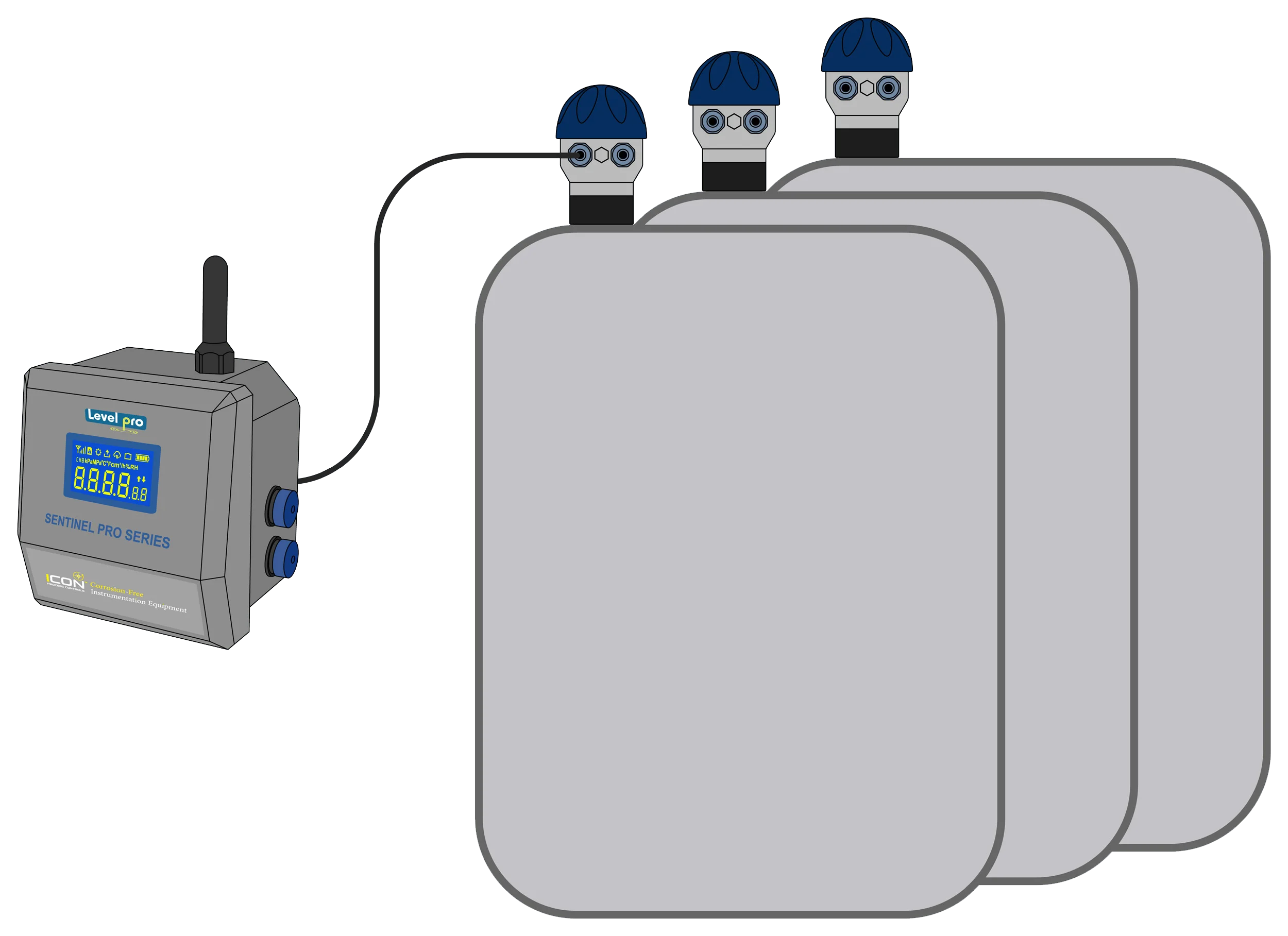

A submersible level sensor, a wireless transmitter, and a remote monitoring station are the fundamental parts of a telemetry remote tank monitoring system. Based on the liquid’s specific gravity, the submersible level sensor is inserted directly into the tank and is used to measure the head pressure of the liquid. This makes it possible to measure accurately even when the tank is full. Because they are unaffected by foam, vapour, turbulence, or condensate, submersible level sensors are regarded as the finest option for telemetry remote tank monitoring. Additionally, they don’t need to be programmed.

The level data from the sensor is transmitted wirelessly to the remote monitoring station. Different wireless technologies, including radio frequency (RF), cellular, and satellite, can be used for this. The remote monitoring station is used to receive and show the level data from the sensor, and it may be situated at a remote site or in a central control room.

The fact that telemetry remote tank monitoring does not require workers to physically access the tank is one of its main benefits. This can significantly lower the possibility of staff injuries and increase overall safety. The liquid level in the tank can be continuously displayed on a local display that can be placed close to the tank. This can help identify leaks or overfills early and stop expensive overspills.

Companies who provide bulk chemicals find that telemetry remote tank monitoring is especially helpful since it enables remote tank monitoring and management. By ensuring that chemicals are delivered to tanks when they are required, stockouts can be avoided and the possibility of production interruptions can be decreased. The data is more handy and effective because it is easily accessible from anywhere and may be shared with other individuals or systems.

Additionally, telemetry remote tank monitoring enables data access on the cloud, enabling simple data access and straightforward tank management. This makes it possible to share data quickly with other individuals or systems and to view data from any location. This might be especially helpful for businesses who have several tanks spread out in various places.

In conclusion, remote tank monitoring through telemetry is an effective method for controlling how liquids and chemicals are used and stored. Workers injury risk can be significantly reduced and overall safety can be increased by doing away with the requirement for personnel to physically access the tank. Because they are unaffected by foam, vapour, turbulence, or condensate, submersible level sensors are regarded as the finest option for telemetry remote tank monitoring. Additionally, they don’t need to be programmed. Tank dipping is also eliminated when a local display is used, making it safer and more effective. Telemetry remote tank monitoring is very helpful for organisations that provide bulk chemicals since it enables remote tank monitoring and administration and makes it possible to access data on the cloud, which is more practical and effective.