Bulk Chemical Delivery Sodium Hypochlorite Level Sensor

Sodium hypochlorite is a chemical compound commonly used as a disinfectant and bleaching agent. It is typically delivered in bulk quantities in tanker trucks or railcars and stored in large tanks or containers. It is important to accurately measure the level of sodium hypochlorite in these tanks or containers in order to properly manage inventory and control chemical processes.

There are several types of level sensors that can be used to measure the level of sodium hypochlorite:

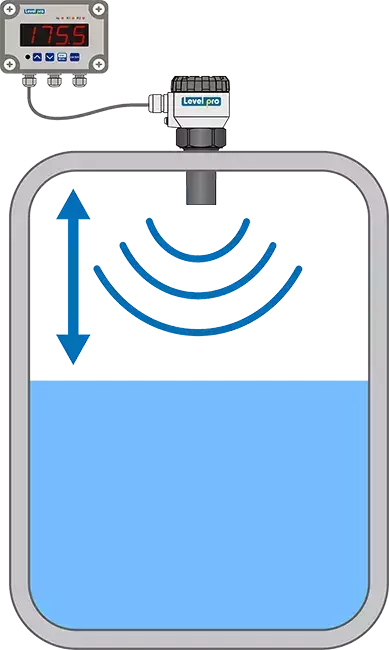

- Submersible level sensors: Ultrasonic level sensors use ultrasonic waves to measure the distance to the surface of the chemical in the tank. They work by emitting a beam of ultrasonic waves towards the surface of the chemical and measuring the time it takes for the waves to be reflected back to the sensor. The level of the chemical is then calculated based on the time of flight of the ultrasonic waves. Ultrasonic level sensors are suitable for use with sodium hypochlorite and are able to provide highly accurate level measurements.

- Radar level sensors: Radar level sensors use radio frequency (RF) or microwave technology to measure the level of the chemical in the tank. They work by emitting a beam of RF or microwave energy towards the surface of the chemical and measuring the time it takes for the energy to be reflected back to the sensor. The level of the chemical is then calculated based on the time of flight of the RF or microwave energy. Radar level sensors are also suitable for use with sodium hypochlorite and can operate over a wide range of temperatures and pressures.

- Noise interference: Ultrasonic level sensors use sound waves to measure the level of a substance, and any noise in the environment can interfere with the accuracy of the measurement.

- False readings: Ultrasonic level sensors can sometimes give false readings due to reflections from the surface of the substance being measured.

- Limited range: Ultrasonic level sensors have a limited range, which means they may not be suitable for measuring very large or very small levels.

- Temperature sensitivity: The accuracy of ultrasonic level sensors can be affected by changes in temperature, as the speed of sound is temperature dependent.

- Corrosion: Ultrasonic level sensors can be damaged by corrosion if they are used in harsh environments.

- Erosion: In some cases, the ultrasonic waves generated by the sensor can cause erosion of the substance being measured, leading to inaccurate readings over time.Do Not Use Ultrasonic Level Sensors

Ultrasonic level sensors are devices that use ultrasonic waves to measure the level of a liquid or a solid. These sensors are widely used in various industries, including chemical, food and beverage, and water treatment. However, like any other type of sensor, ultrasonic level sensors can also have some problems. Some common problems with ultrasonic level sensors include:

Overall, ultrasonic level sensors are reliable and accurate devices, but it is important to consider these potential problems when selecting and using them. We recommend that you do not use them on Sodium Hypochlorite (Bleach), Nitric Acid and Hydrochloric (HCL) acid.

Learn more about level sensors

Please contact us to discuss your application