Easy Installation Of A Chemical Level Sensor

The process of installing a chemical level sensor in a chemical tank is one that calls for careful planning and close attention to detail during the installation process. The first thing that needs to be done in order to get the tank ready to use is to give it a thorough cleaning and check to see that it is clear of any debris or foreign objects. Before the sensor is fitted, the tank should also be inspected for any leaks or damage that would need to be repaired. If there are any, then the sensor won’t work properly.

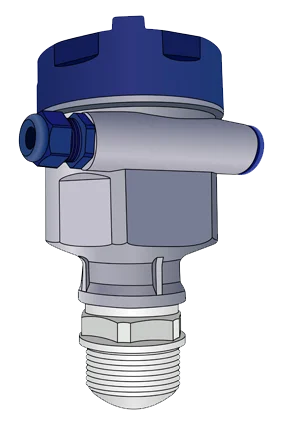

The next thing that needs to be done is selecting the proper sensor for the particular kind of chemical and the environment of the tank. A variety of sensors are developed to function effectively with a wide range of substances and in a variety of settings. Because they may be completely submerged in the liquid without suffering any damage, chemical level sensors that are submersible are an excellent choice for bulk chemicals. PVC, polypropylene, polyvinylidene fluoride (PVDF), or stainless steel may be used in the construction of these sensors.

When the proper sensor has been selected, the next step is to install it in the tank where it will be monitored. It’s possible that this will need drilling holes in the tank or attaching the sensor to a fitting that’s already there. In order to obtain reliable results from the sensor, it must be positioned at the appropriate height and level. In the process of installing the chemical level sensor, the selection of the sensor’s materials for its housing also plays a significant role. For instance, sensors made of PVC or PP are simple to install due to their low weight, whereas sensors made of PVDF or stainless steel may require more specialist equipment for installation. This is because PVDF and stainless steel are more resistant to corrosion.

After the sensor has been mounted, it needs to be attached to a local or remote controller so that the controller can understand the output signal that the sensor is sending. In order to guarantee that the sensor is producing reliable results, it will need to have its calibration adjusted. To do this, you might have to adjust the sensitivity of the sensor or make any number of other necessary adjustments. The sensor will require a power supply in addition to a signal output, with a 4-20mA signal being the most typical output. The signal output from the sensor is then connected to the local or remote controller. This allows the amount of the chemical in the tank to be monitored and controlled.

Last but not least, the sensor needs to be checked to see if it is producing reliable results, and it also needs to be maintained on a routine basis in order to ensure that it remains in excellent working condition. To accomplish this, you may need to clean the sensor and inspect it for any signs of wear or damage. It is essential to ensure that the sensor is functioning correctly and that it is providing readings that are accurate and dependable during the process of installation and maintenance by carefully adhering to the instructions and guidelines provided by the manufacturer.

Learn more about chemical level sensors

Please contact us to discuss your application