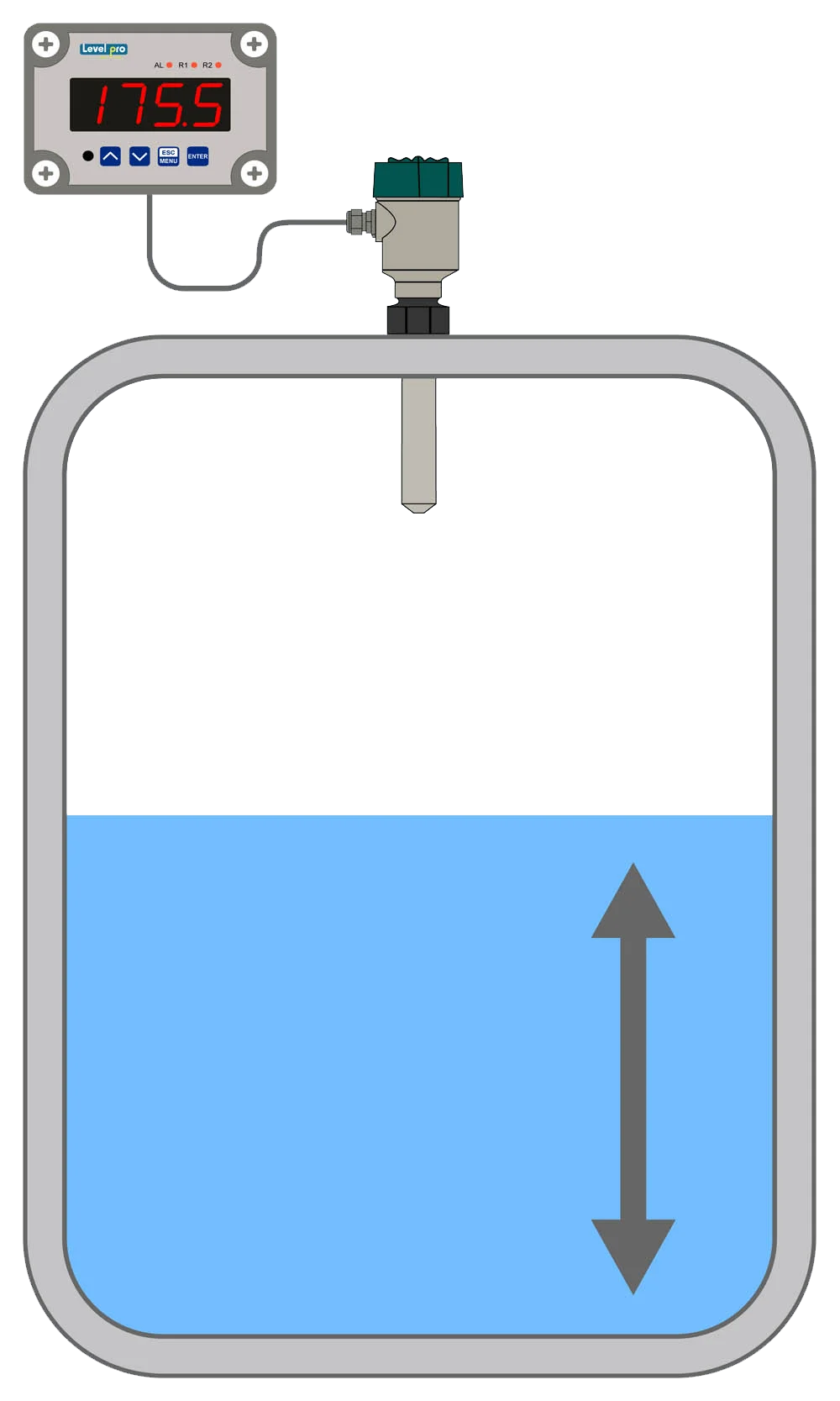

How Does Tank Level Sensors Work?

Tank level sensors are used to measure the level of liquids or bulk chemicals in tanks or other containers. There are several types of tank level sensors, each with their own advantages and disadvantages, and the best option will depend on the specific application and the properties of the liquid or chemical being measured. Some common types of tank level sensors include:

- Submersible level sensors: These sensors are designed to be submerged in the liquid or chemical in the tank. They work by measuring the pressure of the liquid or chemical at the bottom of the tank. As the liquid or chemical level changes, the pressure at the bottom of the tank will change, and the sensor will measure this change to determine the level. Submersible level sensors can be used to measure the level of a wide range of liquids and chemicals, including those that are corrosive or abrasive.

- Ultrasonic level sensors: These sensors use sound waves to measure the level of the liquid or chemical in the tank. They work by emitting a sound wave that travels to the surface of the liquid or chemical and then reflects back to the sensor. The sensor then calculates the distance from the sensor to the surface of the liquid or chemical to determine the level. Ultrasonic level sensors are non-contact and can measure through solid and opaque materials, making them suitable for use in harsh environments.

- Radar level sensors: These sensors use microwaves to measure the level of the liquid or chemical in the tank. They work by emitting a microwave signal that travels to the surface of the liquid or chemical and then reflects back to the sensor. The sensor then calculates the distance from the sensor to the surface of the liquid or chemical to determine the level. Radar level sensors are non-contact and can measure through solid and opaque materials, making them suitable for use in extreme temperatures and pressures.

- Capacitance level sensors: These sensors use the electrical capacitance of the liquid or chemical to measure the level in the tank. They work by creating an electric field between two electrodes, and the liquid or chemical acts as a dielectric material, changing the capacitance between the electrodes. The sensor then calculates the change in capacitance to determine the level of the liquid or chemical. Capacitance level sensors are contact and require the liquid or chemical to be in contact with the sensor.

- Vibrating fork level sensors: These sensors use a vibrating fork to detect the level of the liquid or chemical in the tank. They work by vibrating a fork-shaped probe at a specific frequency, and when the probe comes into contact with the surface of the liquid or chemical, the vibration changes, indicating the level. Vibrating fork level sensors are contact and require the liquid or chemical to be in contact with the sensor.

- Optical level sensors: These sensors use a laser or infrared beam to measure the level of the liquid or chemical in the tank. They work by emitting a beam of light and then measuring the reflection of that light from the surface of the liquid or chemical. The sensor then calculates the distance from the sensor to the surface of the liquid or chemical to determine the level. Optical level sensors are non-contact and can measure through solid and opaque materials, making them suitable for use in harsh environments.

- Float level sensors: These sensors use the buoyancy force of a float to detect the level of the liquid or chemical in the tank. They work by suspending a float on a cable or rod inside the tank, and as the liquid or chemical level changes, the float will rise or fall, indicating the level. Float level sensors are contact and require the liquid or chemical to be in contact with the sensor.

Learn more about tank level sensors

Please contact us to discuss your application