Plain Talk On How Submersible Level Sensors Work

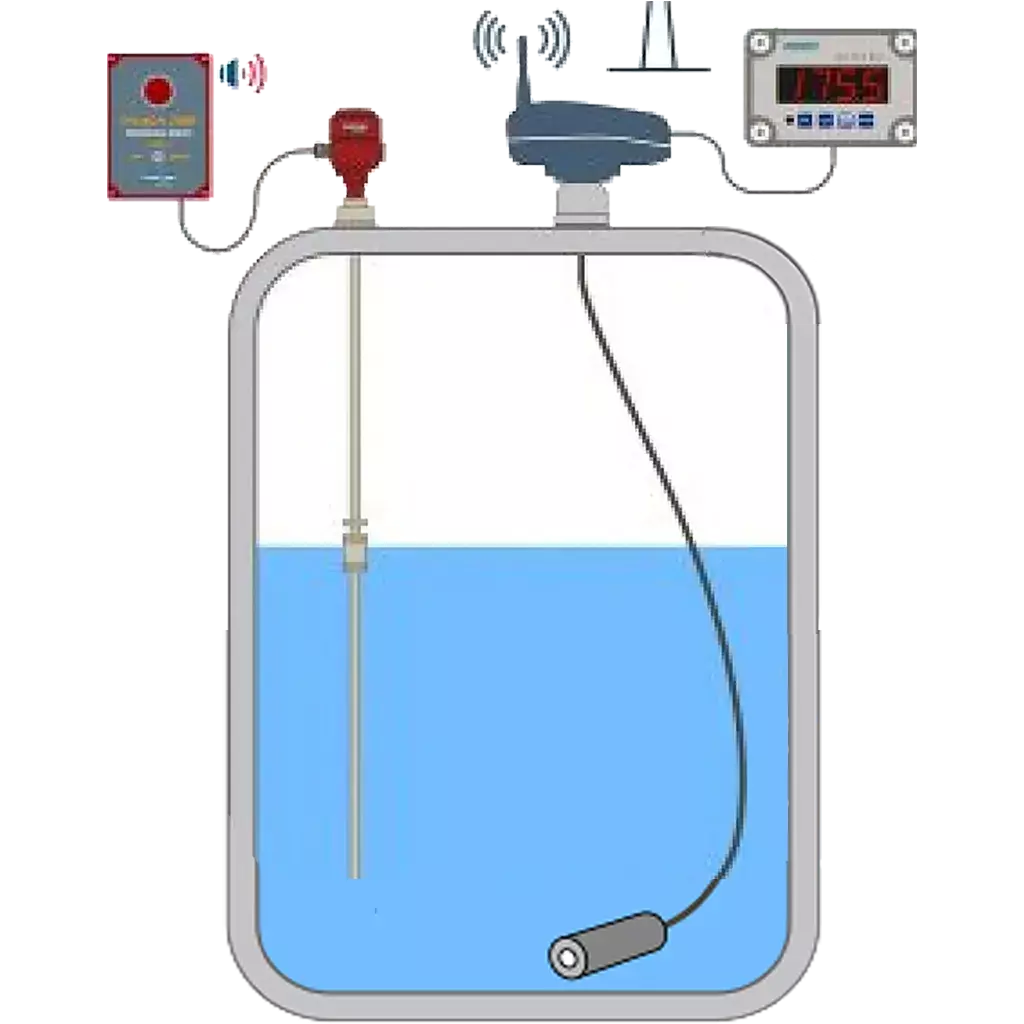

The submersible level sensor determines the depth of the liquid by determining the distance between the sensor probe and the surface of the liquid. A pressure transducer diaphragm forms the sensor probe, which is completely submerged in the medium being measured. The submersible level sensor, which is often referred to as a pressure transducer, is responsible for determining the hydrostatic pressure exerted by the liquid at a particular location.

When the submersible level sensor or pressure transducer is submerged in the liquid, an electrical signal is transmitted to the signal transmitter from the device. The electrical signal is transformed into a loop-powered signal that is powered by 4-20mA by the signal transmitter. This signal can be readily included in a control system.

The 4-20mA signal is a typical current loop that is used for process control and industrial automation; it is a two-wire current loop in which the current is directly proportional to the measured variable. This type of current loop is utilized in a variety of applications.

A microcontroller is also incorporated within the signal transmitter. This microcontroller processes the measurement data and then transmits it to the control system. After that, the data from the measurements can be used by the control system to control the pumps, valves, or other equipment.

The submersible level sensor is built to be strong and long-lasting, making it suited for usage in challenging industrial settings. It is resistant to corrosion, as well as high temperatures, pressure, and vibration, and it can tolerate all of these things.

In addition, submersible level sensors can be utilized in a variety of tanks, including open tanks, closed tanks, and pressurized tanks, as well as a variety of liquids, including water, oil, and chemicals. These applications are made possible by the versatility of this technology. They are also appropriate for use in tanks that contain noisy or agitated liquids and can withstand high levels of noise.

In a nutshell, the submersible level sensor determines the level of the liquid by measuring the distance between the sensor probe and the surface of the liquid. The sensor probe can take the form of either a float or a pressure transducer. The electrical signal is converted by the signal transmitter into a loop-powered signal that is powered by 4-20mA. This signal can simply be included in a control system. The sensor is rugged and long-lasting, making it suited for usage in tough industrial applications. It is also adaptable to a variety of liquids and containers, including tanks.

Learn more about level sensors

Please contact us to discuss your application