Remote Tank Level Monitoring

It might be challenging for plant managers to exactly measure the volumes of fluids while monitoring storage tanks using manual or traditional methods since certain mistakes can occur during the monitoring process. The plant managers are put in a difficult situation as a result. In order to enable better decision-making about the organization’s operations and earnings, both above- and below-ground installations need to be effectively controlled and monitored.

Several organisations are presently benefiting from the Internet of Things (IoT), and its capabilities are being swiftly applied to improve tank storage facilities.

WHAT ARE THE BENEFITS OF A SMART Liquid Level Monitoring System?

There are several different manual techniques and tools that can be used to gauge the level of the tanks. The acceptability of novel level measurement techniques by the industry has significantly changed over time, moving from visual inspections to floats and ultrasonic sensors.

One of the more affordable methods of level measurement is the use of measuring sticks and human inspections; nevertheless, these methods involve a lot of labour and carry a high risk of error. Automated techniques, including floats and underwater pressure transducers, greatly lower the possibility of errors and streamline procedures, which eventually produces better outcomes.

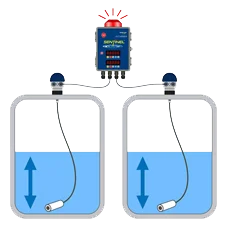

Since these businesses deal with fluid products, there is an increasing need for technology solutions to detect tank levels and fluid quality. In order to get precise tank level readings, most IoT-powered solutions use ultrasonic sensors. The employment of sound waves—which are unaffected by colour, transparency, or reflecting qualities—along with light conditions in these sensors allows for accurate tank level monitoring.

Utilizing a wireless network is a solution that gives real-time data and agility to help firms respond to changes in the industrial landscape. It is also a solution that is feasible from a financial point of view. The employment of a wireless network and ultrasonic sensors in a smart liquid level monitoring system has a variety of advantages, including the following: –

This system’s characteristics include time and money savings, real-time monitoring and quick alarms, and adaptability to shifting industrial needs.

One of the most affordable solutions is to wirelessly connect smart level monitoring devices since it requires fewer infrastructure upgrades and makes it simpler to instal the smart solution. Additionally, plant managers can easily obtain real-time information about tank levels thanks to the sensors’ connectivity. The IoT-powered solution provided by Levelpro is one of the options for integrating smart tank level monitoring.

The Levelpro Intelligent Tank Level Monitoring System

An intelligent tank level monitoring system was developed with the goal of increasing production productivity. The wireless Tank Level Monitoring System provided by Levelpro is perfectly suited for both household and commercial applications and allows for remote control.

With Levelpro’s tank level monitoring solution, you can do predictive maintenance on a range of tanks that have been put in any given location thanks to its strong analytics. It collects the liquid utilisation pattern, eliminating any fluid waste that may have resulted from leaks, and it includes multi-channel alerting functions that assist in identifying any rise or fall in tank levels. These features also aid in detecting any changes in tank levels that might take place. As a result, the terminal can accurately monitor stock availability in real time and effectively manage supply chain operations.

Numerous wireless ultrasonic sensor devices that are easily compatible with the connectivity of LoRaWAN gateways are incorporated into the solution. These devices can be used with a wide range of liquid products, including volatile liquids, fuel, acid, and liquids that prevent corrosion, among others. In order to determine the depth of the tank, Levelpro uses sophisticated mathematical calculations and high-tech parts, such as those that deliver ultrasonic waves to the liquid’s surface. You will be able to get exact information on the level and volume of the liquid by doing this.

A SIMPLE EXAMPLE

Levelpro developed and operated the tank level monitoring technology and related services for a significant citrus juice producer. It was able to considerably boost its production and lessen the issues with product inventories by using the system. The firm first had a lot of trouble in a number of areas, such as calculating the capacity of tanks with unusual shapes, testing different hardware parts on the tanks, transmitting signals via tanks with higher heights, and gathering data from several tanks of varied types.

Keeping an eye on the levels and volume measurements of the juice being kept in the tanks is now much easier owing to the tank level monitoring system offered by Levelpro.

Employees were able to track the juice levels in the 45′ (13.7 m) storage tanks/tankers in real-time because to Levelpro’s ability to deliver end-to-end services. Additionally, it helped them view real-time volume readings of the juice being stored in the tankers from a distance. These storage facilities were located in regions where it often got as cold as -20 degrees Fahrenheit. However, the customer was able to deploy and use the system more easily with the help of Levelpro’s powerful in-built calculative features.

The data gathered from the juice tanks is recorded on a cloud server, and it is this data that is shown on the dashboards run by the user’s mobile devices and the internet. As a result of the implementation of this solution, the customer was able to get real-time readings of the juice level in the tanks, set threshold levels to get immediate alerts, use advanced analytics to analyse and process data, create a streamlined management process for easy process execution, and do a lot more.

All of the realistic requirements for the company are considered in the solution. It can be used to both stationary and moving tankers. It is highly adaptable and may be tailored to measure the liquid’s volume in accordance with the specifications.

Good choices for an intelligent tank level monitoring system include the following: –

Fuel-powered Internet of Things solutions are essential for reducing fuel waste and giving managers access to data that can be used to improve choices. Additionally, managers can more easily focus on several criteria at once, such as overflows, fuel supply problems, leakage areas, etc. Utilizing advanced sensors and gateways, the smart tank level monitoring solution carries out automatic monitoring of the fuel levels within the tank. This helps identify any potential leaks, which reduces any wasted gasoline, and ensures that proper stock levels are maintained at all times.

Beverages – A smart tank level monitoring system works incredibly well with all sorts of tanks, including small storage tanks. This provides the capability to remotely check tank levels. It is possible to detect the presence of pollutants and get real-time updates on those discoveries by integrating a system driven by the internet of things (IoT) to assess beverage levels. Additionally, it determines the precise amount of production required to provide a sufficient supply of beverage stock and so ensures its availability.

The ability to adopt a more strategic approach to maintaining tank supplies is made possible by a smart tank level monitoring technology, which boosts product sales and ensures quality.

Learn more about level sensors

Please contact us to discuss your application