Safety Issues Surrounding Dipping a Tank to Determine Level

Dipping a tank, also known as manual tank gauging, involves physically measuring the level of liquid in a tank by inserting a dipstick or measuring tape into the tank and reading the liquid level from the markings on the dipstick or tape. While this method can be a simple and inexpensive way to check the liquid level in a tank, it has several limitations and drawbacks that make it less suitable as a primary method for tank level indication:

- Safety concerns: Dipping a tank can be dangerous, particularly if the liquid stored in the tank is hazardous or flammable. It requires operators to enter the tank and physically handle the dipstick or measuring tape, which can expose them to the risks of fire, explosion, or toxic fumes.

- Limited accuracy: The accuracy of manual tank gauging is dependent on the operator’s skill and experience. It can be affected by factors such as the operator’s ability to read the dipstick or tape, the condition of the dipstick or tape, and the operator’s ability to accurately estimate the level of liquid in the tank.

- Limited frequency: Manual tank gauging is a time-consuming process that can only be performed periodically. This means that the level of liquid in the tank can change between measurements, which can lead to inaccurate readings and a lack of real-time data.

- Limited remote access: Manual tank gauging requires physical access to the tank, which can be difficult or impossible in remote locations or hazardous environments.

- Inefficiency: Dipping a tank can be an inefficient process that requires a significant amount of time, labor, and resources.

- Environmental factors: Dipping a tank can be affected by environmental factors such as temperature and pressure changes, which can lead to inaccurate readings.

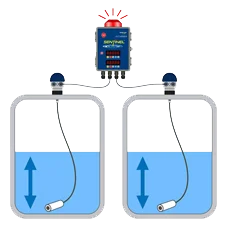

For these reasons, manual tank gauging is generally considered to be less suitable as a primary method for tank level indication. Instead, other methods such as submersible level sensors, float gauges, ultrasonic level sensors, capacitance or conductivity level sensors, or radar level sensors are considered to be more suitable as they are more accurate, efficient, and safer to use.

Learn more about level sensors

Please contact us to discuss your application