Selecting a Tank Level Sensor for Sodium Hypochlorite

Sodium hypochlorite is a chemical compound with the formula NaClO. It is a pale greenish-yellow liquid that is commonly used as bleach or disinfectant. When dissolved in water, it releases chlorine, which makes it an effective sanitizer and disinfectant. Sodium hypochlorite is widely used in many different industries, including water treatment, food and beverage processing, and swimming pool maintenance. It is also a common ingredient in household cleaning products, such as laundry detergents and disinfectants.

Sodium hypochlorite is a strong oxidizer, which means that it can cause fires or explosions if it comes into contact with certain materials. It is also corrosive to most metals, and it can cause skin and eye irritation if it comes into contact with skin or eyes. Therefore, it is important to handle sodium hypochlorite with care and to use appropriate protective equipment when working with it.

It’s pH range is 11-13, which makes it highly alkaline. Therefore, it is important to use materials that are resistant to corrosion and can withstand the alkaline environment.

When selecting a tank level sensor for sodium hypochlorite, it’s important to consider the chemical properties of the solution, as well as the specific process conditions and the requirements of the application.

Chemical Properties: Sodium hypochlorite is a strong oxidizer and is corrosive to most metals. It also has a pH range of 11-13 which makes it highly alkaline. Therefore, the sensor must be made of a material that is resistant to corrosion and can withstand the alkaline environment. PVC, PTFE, and PVDF are commonly used materials for level sensors in sodium hypochlorite applications.

316SS Sensors are NOT RECOMMENDED

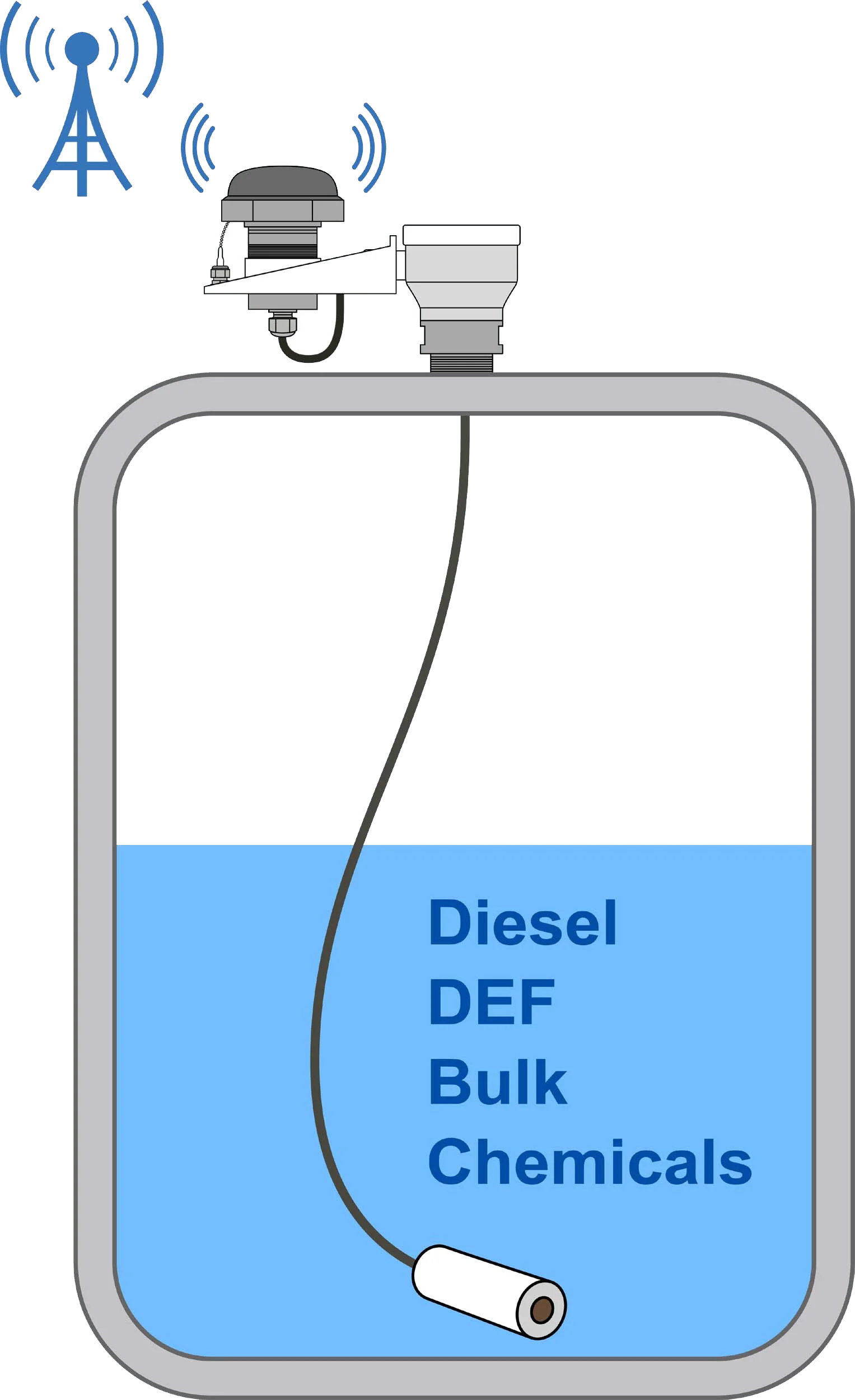

Type of Sensor:

Ultrasonic-Sensors are Not Recommended

and radar sensors are suitable for sodium hypochlorite applications because they do not come into contact with the liquid and are not affected by the corrosive properties of the solution. Ultrasonic sensors are suitable for liquid level detection, whereas radar sensors are suitable for continuous level measurement.

Process conditions: The sensor must be able to operate in the specific process conditions, such as temperature, pressure, and flow rate. Sodium hypochlorite is typically stored at room temperature, but the temperature may vary depending on the application. The sensor should also be able to handle high pressure if the system is pressurized.

Installation: The sensor should be easy to install and maintain, and it should be easy to access for cleaning and calibration.

Cost: The cost of the sensor should also be considered, as well as the cost of installation, maintenance, and replacement parts.

Overall, it’s important to consult with the manufacturer or a sensor expert to ensure that the sensor you choose is compatible with the liquid being measured and that the sensor will last in your specific application.

Learn more about analytical sensors

Please contact us to discuss your application