Selecting Liquid Level Sensors: A Comprehensive Guide

Choosing the right liquid level sensor is crucial for efficient industrial processes. The correct sensor ensures accurate measurements, operational safety, and compatibility with specific applications. From chemical processing to water treatment, liquid level sensors play a critical role in monitoring and controlling liquid levels within tanks and pipelines. Each industry and application has unique requirements, making it essential to consider various factors during the selection process. This comprehensive guide will explore the key criteria for selecting liquid level sensors and provide detailed insights into the available options from Icon Process Controls. By understanding the strengths of submersible, radar, ultrasonic, and float level sensors, you can make an informed decision that optimizes performance while minimizing maintenance and downtime.

In this post, we will detail critical selection criteria, examine specific sensor types, and highlight the innovative solutions offered by Icon Process Controls. Whether your application involves corrosive liquids, extreme environments, or precise measurements, this guide has you covered.

Key Criteria for Selecting Liquid Level Sensors

1. Understanding the Liquid Characteristics

The type of liquid is the most critical factor. Ensure the sensor materials are compatible with the liquid’s chemical properties. For example:

- Corrosive Liquids: Use sensors made from materials like PVDF, PTFE, or 316SS.

- Viscous Liquids or Slurries: Radar sensors excel in applications involving thick or particulate-laden liquids.

- Clean vs. Dirty Liquids: Ultrasonic sensors work well with clean liquids, while radar sensors handle dirty or turbulent surfaces effectively.

Temperature and pressure also influence sensor performance. Submersible and radar sensors from Icon Process Controls are designed to withstand extreme conditions.

2. Measurement Range and Accuracy

Each sensor type has specific ranges and accuracy levels. Match the sensor’s capability to your tank dimensions and application requirements:

- Submersible Sensors: Ideal for deep tanks or wells with ranges up to several meters.

- Radar Sensors: Suitable for tall or narrow tanks with high precision even in complex conditions.

- Ultrasonic Sensors: Effective for medium-range applications with accuracy suitable for most industrial needs.

- Float Sensors: Best for simpler applications requiring basic on/off level detection.

Always consider application-critical accuracy requirements. For example, pharmaceutical processes demand sensors with ±0.1% accuracy for precise control.

3. Application Environment

The operating environment can impact sensor performance. Factors to consider include:

- Tank or Vessel Shape: Submersible sensors fit narrow wells, while radar sensors are versatile for large, irregular tanks.

- External Conditions: Sensors in hazardous areas require explosion-proof designs. The LevelPro 100 Series submersible sensor from Icon Process Controls is IP68-rated, making it ideal for submerged or outdoor conditions.

4. Ease of Installation and Maintenance

Choose sensors that are easy to install and maintain:

- Float Sensors: Simple to install and maintain but require physical tank access.

- Radar Sensors: Non-contact installation reduces wear and maintenance needs.

- Ultrasonic Sensors: Mount externally for easy servicing without disrupting operations.

- Submersible Sensors: Require minimal upkeep when used with compatible liquids.

5. Output Compatibility

Sensors must integrate seamlessly with existing monitoring systems. Common outputs include:

- Analog (4-20mA): Reliable and compatible with most industrial systems.

- Digital Protocols (Modbus, IO-Link): Allow advanced diagnostics and remote monitoring.

Icon Process Controls offers sensors with both analog and digital outputs, ensuring compatibility across applications.

Types of Liquid Level Sensors

1. Submersible Liquid Level Sensors

100 Series • 200C Series • 300S Series • TankPro

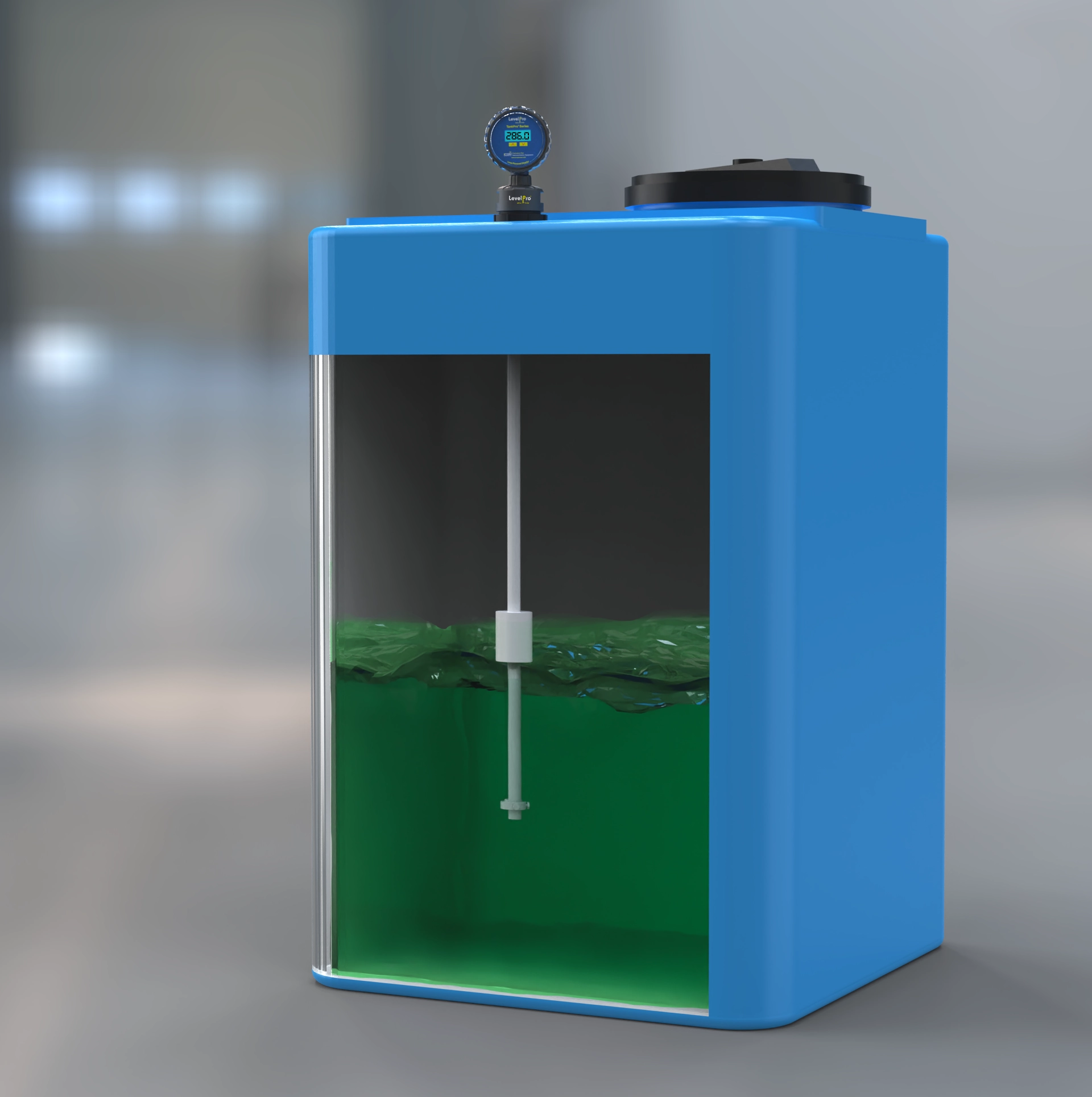

Submersible sensors are designed for applications requiring direct contact with the liquid. The LevelPro 100 Series Submersible Sensor from Icon Process Controls is a top choice for deep tanks, wells, or reservoirs. Its rugged design resists corrosion and ensures long-term reliability. These sensors work by measuring hydrostatic pressure, making them ideal for monitoring water levels, wastewater, or chemical tanks.

Advantages:

- Accurate in deep and narrow tanks.

- Resistant to corrosion when constructed with PVDF or PTFE.

- Minimal maintenance in clean liquids.

Applications:

- Water and wastewater treatment.

- Chemical storage.

- Oil and gas industry.

2. Radar Liquid Level Sensors

ProScan 3 • ProScan 2 • ProScan • MLR-70 Guided Wave

Radar sensors use electromagnetic waves to measure liquid levels without physical contact. The LevelPro ProScan 3 80GHz Radar Sensor excels in harsh environments and delivers unmatched accuracy, even with turbulent or foamy liquids.

Advantages:

- High accuracy in challenging conditions.

- Non-contact measurement eliminates wear and contamination.

- Suitable for corrosive and high-temperature applications.

Applications:

- Chemical processing.

- Food and beverage production.

- Oil refineries.

3. Ultrasonic Liquid Level Sensors

Ultrasonic sensors emit sound waves to determine liquid levels. The UltraPro 2000 Ultrasonic Sensor from Icon Process Controls is a versatile solution for medium-range applications requiring cost-effective, non-contact measurements.

Advantages:

- Non-contact and cost-effective.

- Reliable in clean liquids.

- Easy installation and maintenance.

Applications:

- Municipal water systems.

- Tank farms.

- General industrial processes.

4. Float Liquid Level Sensors

CFL Float Liquid Level Sensor • PLF • PLS • FloatPro

Float sensors are a simple, robust solution for basic liquid level monitoring. The LevelPro CFL Series Float Sensor provides reliable performance for straightforward applications.

Advantages:

- Simple design with low cost.

- Easy installation.

- Long operational lifespan.

Applications:

- Sump pits.

- Basic on/off level detection.

- Non-corrosive liquid storage.

Selecting the Right Sensor for Your Needs

Choosing the correct liquid level sensor involves balancing functionality, cost, and compatibility. Icon Process Controls offers a comprehensive range of sensors tailored to diverse industrial applications. For complex or high-precision tasks, radar or submersible sensors may be ideal. If budget and simplicity are priorities, float or ultrasonic sensors may suffice.

Why Choose Icon Process Controls?

Icon Process Controls provides innovative solutions designed to meet industry-specific needs. Their sensors are made from corrosion-resistant materials and offer advanced features like wireless monitoring. The company’s expertise ensures you’ll find the perfect sensor for your application.

Conclusion

Selecting liquid level sensors requires understanding your application’s unique requirements. Factors like liquid type, environment, and output compatibility influence your decision. Submersible, radar, ultrasonic, and float sensors from Icon Process Controls provide reliable options for diverse industries. Whether you prioritize accuracy, ease of use, or cost-effectiveness, Icon Process Controls offers solutions tailored to your needs.

Optimize your operations by choosing the right liquid level sensor today. Contact Icon Process Controls for expert guidance and top-quality instruments.