Selecting The Right Chemical Level Switch

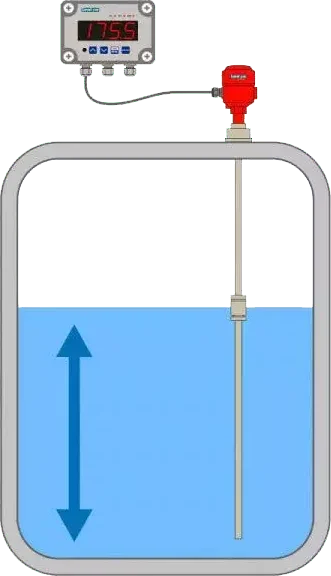

A chemical level switch is installed to monitor the liquid level in a chemical tank. In bulk chemical tanks, it is crucial to install a level switch for a variety of reasons. First and foremost, it permits monitoring and control of the liquid chemical concentration within the tank. This is essential for safety, as overfilling or running out of chemicals can result in spills and other hazardous situations. High chemical level and low chemical level switches can avert these eventualities by emitting an alarm or cutting off the flow of chemicals when particular levels are reached.

There are numerous types of chemical level switches, each with its own benefits and drawbacks. Float level switches are a frequent variety. This form of chemical level switch employs a buoyant device, such as a float, that rises and falls with the liquid level. When the float reaches a specified level, it is connected to a switch mechanism that initiates an alarm or shut-off valve. Float-type chemical level switches are generally straightforward and affordable, and they can be utilised for both high and low level alarms.

The vibration level switch is another sort of chemical level switch. This type of switch employs a mechanical vibration sensor that detects changes in liquid level by sensing the change in vibration induced by the flow of liquid. Vibration level switches are often more dependable and precise than float level switches, and they are frequently employed in industrial applications.

The capacitive level switch is the third type of chemical level switch. This sort of switch detects level changes using the change in capacitance (the ability to store electrical charge) produced by the presence of a liquid. When monitoring high amounts of conductive liquids, capacitive level switches are especially beneficial. They are sensitive to changes in the level of the liquid and may detect even minute differences.

In addition to these varieties, there are also available ultrasonic, radar, and laser level switches. Each of these chemical level switches has its own advantages and disadvantages and is suited for a particular purpose.

Overall, chemical level switches play a significant role in preserving the safety and efficiency of chemical storage and handling operations. They provide a cost-effective method for preventing overfilling and depletion of chemicals, hence lowering the possibility of chemical spills and other hazardous circumstances. Moreover, as workplace safety requirements become more stringent, it is essential to install and maintain chemical level switches in accordance with the rules to avoid fines.

Learn more about level sensors & level switches

Please contact us to discuss your application