Simple Steps to Chemical Level Sensor Installation

In the majority of tank level applications, the following steps are needed to install a chemical level sensor in a chemical tank:

Preparing the Tank: The first step is to prepare the tank by thoroughly cleaning it and making sure it is free of any debris or foreign materials. Before the chemical level sensor is put in, the tank should also be checked for any leaks or damage that may need to be fixed.

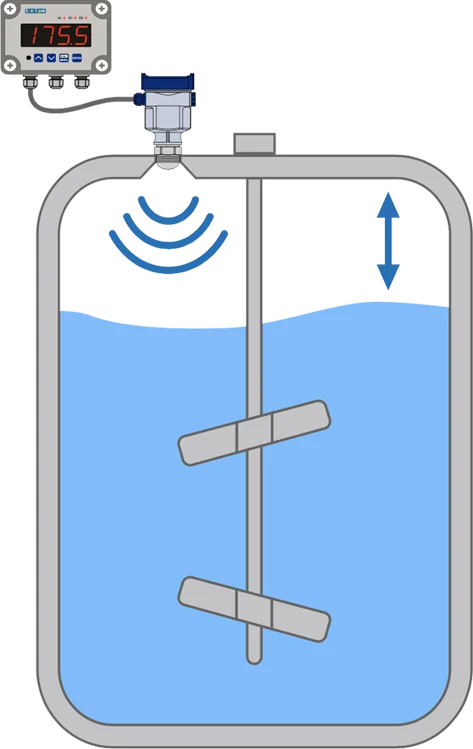

Choosing the Right Sensor: The next step is to choose the right sensor for the type of chemical and tank environment. Different chemical level sensors are made to work with different chemicals and in different places. For example, submersible chemical level sensors are a good choice for bulk chemicals because they can be fully submerged in the liquid without getting damaged.

Installing the Sensor: Once the right chemical level sensor has been chosen, it needs to be put in the tank. This could mean making holes in the tank or attaching the sensor to a fitting that is already there. To get accurate readings, the chemical level sensor should be placed at the right height and level.

Wiring and Calibration: The sensor will then need to be connected to a local or remote controller, which will interpret the chemical level sensor’s output signal. To make sure that the sensor is giving accurate readings, it will also need to be calibrated. This could mean adjusting the sensor’s sensitivity or making any other changes that are needed.

Connecting Power and Signal: The chemical level sensor needs a power source and a signal output. A 4-20mA signal is the most common signal output. The signal from the chemical level sensor is then connected to the local or remote controller. This allows the level of the chemical in the tank to be monitored and controlled.

Testing and Maintenance: Lastly, the chemical level sensor should be tested to make sure it is giving accurate readings. The sensor should also be maintained regularly to keep it in good shape. This could mean cleaning the chemical level sensor and looking for any wear or damage.

It’s important to remember that the choice of materials for the chemical level sensor also affects how it’s put in. For example, chemical level sensors made of PVC or PP are easy to install because they are light, while sensors made of PVDF or stainless steel may need more specialized tools for installation.

Overall, installing a chemical level sensor in a chemical tank requires careful planning, the right sensor choice, and following the instructions from the manufacturer. It also needs to be taken care of regularly to make sure the sensor is giving correct and reliable readings.

Learn more about level sensors

Please contact us to discuss your application