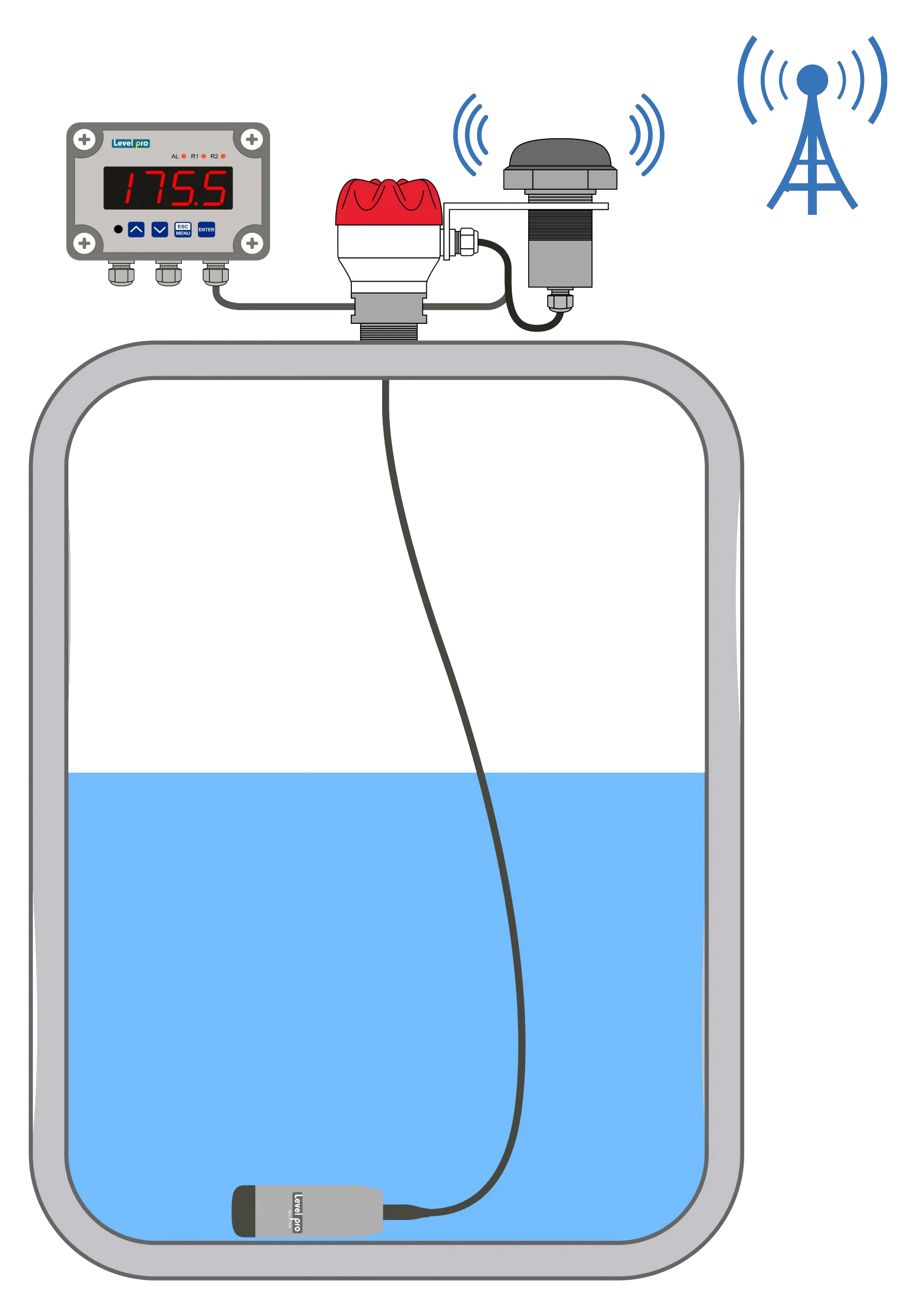

Simple Tank Level Measurement

The method of determining the amount of a corrosive liquid in a container is referred to as liquid level measurement. Corrosive chemicals are compounds that, when in contact with materials or equipment, can cause harm and damage such as corrosion. To avoid spills, leaks, and other risks, it is critical to properly and safely measure the level of these substances.

There are various methods for measuring the level of corrosive liquids, each with its own set of pros and disadvantages. Among the most common approaches are:

Submersible tank level sensors are considered to be the best solution for corrosive as well as non-corrosive chemicals. The submersible tank level sensor the Levelpro 100 series has been designed to sink to the bottom of the tank and provide very accurate information as to the amount of liquid in the tank. The 100 Series submersible is available in PVC, PP, PVDF, PTFE Teflon® and 316SS materials making it an excellent choice for a broad range of liquid media.

Visual inspection: This method involves physically inspecting the container to determine the liquid level. This is the most basic and simplest procedure, but it can be difficult to perform precisely and may not be safe if the chemical is poisonous or otherwise dangerous.

Float level sensors: The Levelpro CFL continuous float employs a float that lies on top of the liquid and is linked to a sensor that delivers a signal indicating the liquid’s level. This procedure is quite easy and affordable, however it may not work well with thick or dense liquids.

Ultrasonic level sensors: This approach use sound waves to determine the distance between the sensor and the liquid’s surface. Based on this distance, the sensor determines the liquid level. Although this approach is relatively accurate and may be used with a broad variety of liquids, is often unreliable in applications that involve foam, vapor, condensate or turbulence. The submersible tank level sensor is a much better choice for difficult level measurement.

Conductivity level sensors: This approach measures the level of liquid using electrical conductivity. To detect the liquid level, the sensor conducts an electrical current through the liquid and measures the resistance. Although this approach is relatively accurate and may be used with a broad variety of liquids, it may be more expensive than other procedures.

Radar level sensors: This approach use radar waves to determine the distance between the sensor and the liquid’s surface, this is also referred to as ‘the time of flight’ Based on this distance, the sensor determines the liquid level. Although this approach is relatively accurate and may be used with a broad variety of liquids, it may be more expensive than other procedures.

When measuring corrosive liquids, it is critical to use chemical-resistant materials such as PVC, PP, PVDF, and PTFE. and to take adequate safety precautions. Some corrosive chemicals can destroy equipment and endanger humans, therefore they must be handled with caution.

In summary, corrosive chemical liquid level measurement is a procedure for determining the amount of corrosive liquid in a container. There are various methods for measuring the level of corrosive liquids, each with its own set of pros and disadvantages. When measuring corrosive liquids, it is critical to use chemical-resistant materials and to take adequate safety precautions.

You can visit our website to determine what materials are best suited for your application.

Here is the link to the chemical compatibility guide

Learn more about level sensors

Please contact us to discuss your application