Straight Talk On A Chemical Level Switch

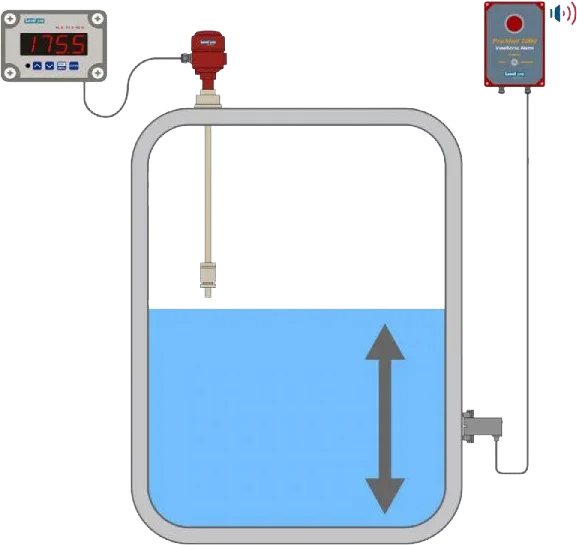

The liquid level in a chemical tank can be monitored with the help of a chemical level switch. There are a number of reasons why it’s crucial to have a chemical level switch installed in your bulk chemical tanks. Primarily, it permits the liquid chemical tank level to be tracked and managed. This is crucial for reasons of safety, as spills or other harmful situations might result from overfilling or running out of chemicals. These potential disasters can be avoided with the use of switches that either raise an alarm or immediately cut off the supply of chemicals when specified thresholds are met.

Chemical level switches come in a variety of forms, each with its own set of pros and cons. The float level switch is a typical example. A float or other buoyant object that rises and falls with the liquid level is used in this chemical level switch. Whenever the float reaches a predetermined level, a valve or alarm is triggered. High and low level alarms can be easily set with a float type chemical level switch that is both simple and affordable.

A vibration level switch is another kind of chemical level switch. A mechanical vibration sensor is employed in this switch design to detect fluctuations in liquid level through monitoring the mechanical vibrations produced by the liquid’s motion. In most cases, vibration level switches are more accurate and dependable than float level switches, making them the preferred choice for usage in industrial settings.

Capacitive level switches are the third variety of chemical level switch. Liquid’s effect on a switch’s capacitance (its ability to hold electrical charge) is used by this switch’s level detection mechanism. It is very helpful to utilise capacitive level switches for keeping tabs on the volume of highly conductive liquids. They detect even minute shifts in the liquid level due to their sensitivity to level fluctuations.

Other level switches, such as ultrasonic, radar, and laser level switches, are also on the market. Level switches come in a variety of designs, and each one is best suited to a certain task.

With that in mind, it’s clear that level switches play a crucial role in the safe and effective management of chemical storage and handling. They offer a cheap solution to the problem of chemical leaks and shortages, and they do so without sacrificing safety. Furthermore, it is crucial to verify that the chemical level switches are installed and maintained in accordance with the standards to prevent any penalties in light of the expanding rules for workplace safety.

Learn more about level sensors & level switches

Please contact us to discuss your application