Understanding EPA Tier 4 Emissions Requirements and Tank Level Sensors and Displays

The EPA Tier 4 emissions standards are designed to reduce emissions of particulate matter (PM) and nitrogen oxides (NOx) from diesel engines used in mobile generators and other nonroad applications. The standards apply to engines with a power output of more than 25 horsepower, and they are based on a sliding scale that takes into account the engine’s horsepower, intended use, and model year.

To meet the EPA Tier 4 emissions standards, manufacturers must use advanced emission control technologies, such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems. These technologies work by trapping or reducing the emissions of PM and NOx, respectively.

In general, the more powerful the engine, the stricter the emissions standards it must meet. For example, an engine with a power output of more than 750 horsepower must meet the most stringent Tier 4 Final standards, which were implemented in 2015.

It is important for manufacturers and users of diesel generators to be aware of the Tier 4 standards and ensure that their engines are compliant. Failure to meet these standards can result in fines and other penalties.

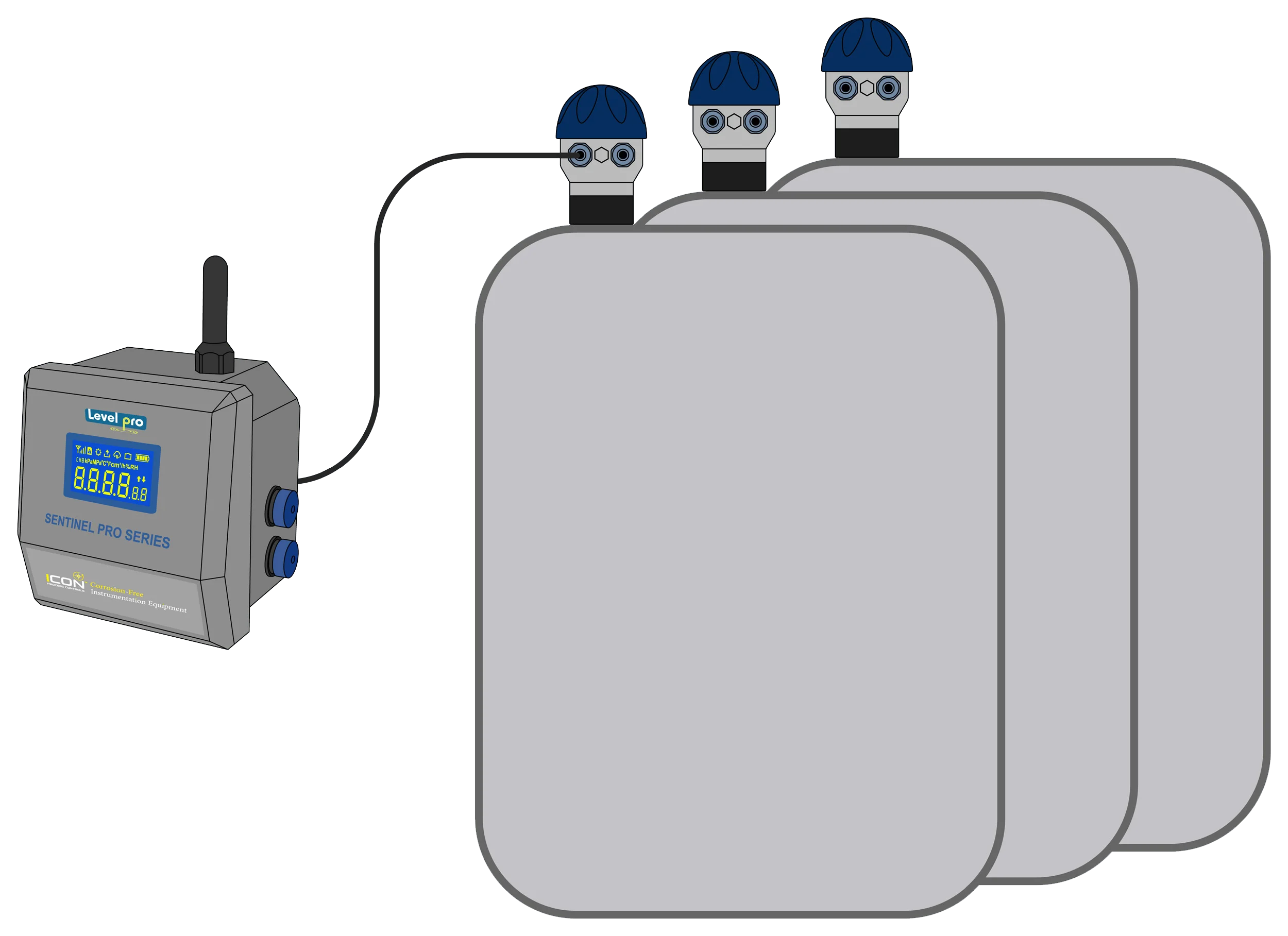

Submersible level sensors are sensors that are designed to be submerged in a liquid, such as water or fuel, and measure the level of the liquid. They are commonly used in applications where it is not possible or practical to install a sensor above the liquid level, such as in tanks or reservoirs.

There are several types of submersible level sensors, including hydrostatic, pneumatic, and ultrasonic sensors. Hydrostatic sensors measure the hydrostatic pressure of the liquid to determine the level. ch as air, to measure the liquid level.

Submersible level sensors have a number of advantages, including the ability to operate in harsh environments, the ability to measure the level of the liquid accurately, and the ability to measure the level of the liquid remotely. However, they can be more expensive and complex to install and maintain than other types of level sensors.

It is important to choose a submersible level sensor that is compatible with the liquid being measured, has the necessary accuracy and range, and is able to withstand the environmental conditions of the application.

Please contact us to discuss your application