Understanding How Submersible Tank Level Sensors Work

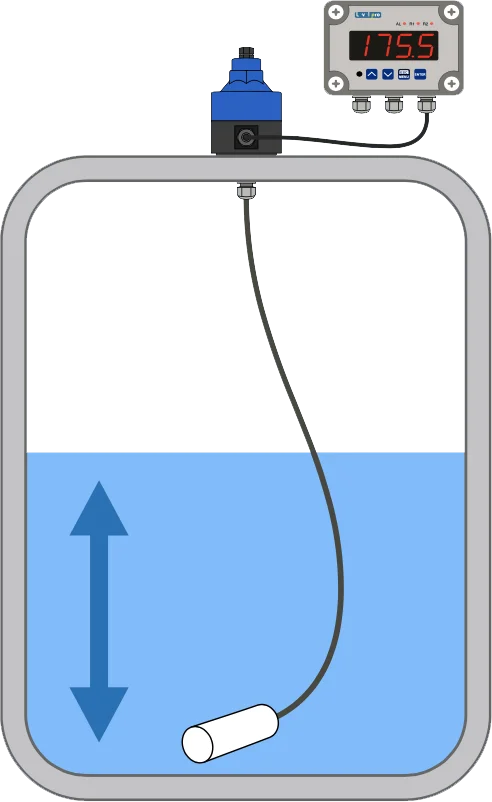

The level of a liquid that a submersible level sensor is monitoring is determined by the fact that the sensor itself is immersed in the liquid. In most cases, they are made up of a sensor head and a cable that is used to connect the sensor head to the control system. The sensing element, which is built to detect the level of the liquid, and the transmitter, which is designed to deliver the level information to the control system, are both contained within the sensor head.

There are numerous varieties of submersible level sensors, each of which has its unique technique for determining how high the level of the liquid has risen. The following are some of the most prevalent types:

Hydrostatic pressure sensors: These sensors measure the hydrostatic pressure of the liquid, which is the pressure exerted by the weight of the liquid. Hydrostatic pressure is the same as atmospheric pressure. A pressure transducer is housed within the sensor head. This device is responsible for converting the hydrostatic pressure into an electrical signal that is then transmitted to the control system. Hydrostatic pressure sensors offer a high degree of accuracy and can be utilised in a variety of contexts and applications that call for a high degree of precision.

Float sensors: These sensors make use of a float that moves up and down in response to changes in the level of the liquid. The movement of the float causes it to activate a switch or transmit a signal to the control system as it goes up and down. Float sensors are ideal for applications that demand only a moderate amount of precision, as they are not only straightforward but also very inexpensive.

Optical sensors: These sensors measure the level of the liquid by utilising a light source and a detector in conjunction with one another. The light that is reflected off the surface of the liquid and is measured by the sensor as the level of the liquid rises and falls in the container. Optical sensors are suitable for applications that require a high level of precision because of their high level of accuracy.

Because they are made to be submerged in liquid and are able to resist the harsh conditions that are typically seen in bulk chemical applications, submersible level sensors are the superior option for measuring levels in these kinds of applications. Because they are often composed of materials that are resistant to corrosion and can tolerate high temperatures, this makes them an excellent choice for use in chemical storage tanks, process vessels, and other equipment that is subjected to severe chemicals. They are also simple to set up, and one may use them to determine the concentration of a large number of different substances, such as acids, bases, and solvents, among other things.

In a nutshell, submersible level sensors are instruments that determine the depth of a liquid by measuring how deeply they are immersed in that liquid. In most cases, they are made up of a sensor head and a cable that is used to connect the sensor head to the control system. They are the best option for bulk chemical applications because they are designed to be submerged in liquid, they are able to withstand the harsh conditions that are typically found in these applications, they can be used to measure the level of a wide variety of chemicals, including acids, bases, and solvents, and they are simple to instal. Because of these characteristics, they are the best choice for bulk chemical applications.

Learn more about level sensors

Please contact us to discuss your application