What to Consider when Selecting a Bulk Chemical Tank Level Sensor

There are several factors to consider when selecting a bulk chemical level sensor:

- Chemical compatibility: It is important to choose a level sensor that is compatible with the chemical being measured. This includes considering the chemical’s pH, temperature, and specific gravity, as well as any corrosive or abrasive properties.

- Tank size and shape: The size and shape of the tank or container in which the chemical is stored should be taken into account when selecting a level sensor. This will help to ensure that the sensor is able to accurately measure the level of the chemical over the entire range of the tank.

- Accuracy: The accuracy of the level sensor is an important factor to consider, as it will determine the precision of the level measurements. Consider the required accuracy of the measurements and choose a sensor that is able to meet this requirement.

- Operating conditions: The level sensor should be able to operate reliably under the specific conditions in which it will be used. This includes considering factors such as temperature, pressure, and any potential interference from other equipment or materials in the area.

- Cost: The cost of the level sensor should also be considered, as it will need to be balanced against the accuracy and reliability requirements of the application.

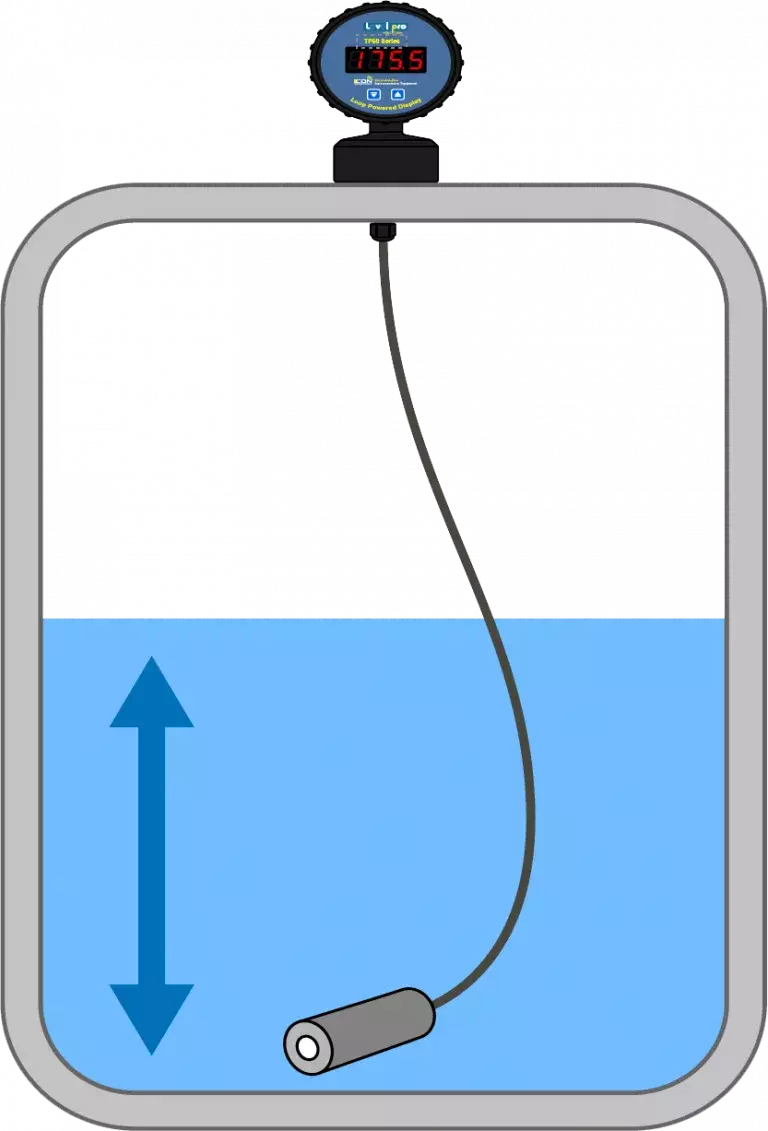

- A submersible level sensor is a type of level sensor that is designed to be submerged in the liquid being measured. They are often used to measure the level of bulk chemicals, as they offer several advantages over other types of level sensors:

- Chemical compatibility: Submersible level sensors are typically made of materials that are resistant to chemical attack and corrosion, making them suitable for use with a wide range of chemicals.

- Accuracy: Submersible level sensors are able to provide highly accurate level measurements, as they are in direct contact with the chemical being measured. This can be particularly important in applications where precise level control is required.

- Easy installation: Submersible level sensors are easy to install, as they do not require any external hardware or mounting equipment. They can simply be lowered into the tank or container and left in place to measure the level of the chemical.

- Rugged design: Submersible level sensors are designed to withstand the harsh conditions often found in chemical storage and processing environments. They are typically robust and durable, making them suitable for use in demanding applications.

Overall, submersible level sensors are a good choice for bulk chemical level measurement due to their chemical compatibility, accuracy, easy installation, and rugged design.

In summary, when selecting a bulk chemical level sensor, it is important to consider factors such as chemical compatibility, tank size and shape, accuracy, operating conditions, and cost.

Learn more about bulk chemical tank level sensors

Please contact us to discuss your application