Why are tank level sensors used on double wall tanks

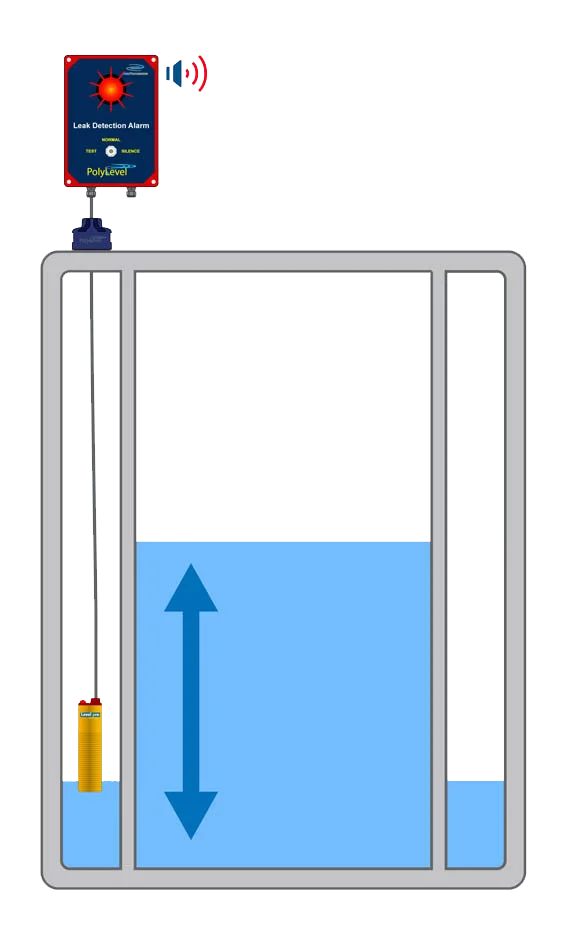

It is important to select the correct tank level sensors for double wall tanks because the sensors play a critical role in monitoring the integrity of the tank. Double wall tanks are designed with an inner and outer wall, with a space between the walls.

Double wall tanks and the role of tank level sensors in monitoring their integrity.

The interstitial space is used to detect leaks in the inner wall of the tank. If a leak develops in the inner wall, the liquid stored in the tank will escape into the interstitial space, causing the level of liquid in the space to rise.

Tank level sensors are used to monitor the level of liquid in the interstitial space. These sensors can be placed in the space at various points to provide a continuous measurement of the level of liquid. If the level of liquid in the interstitial space rises above a certain point, it indicates that there is a leak in the inner wall of the tank.

By monitoring the level of liquid in the interstitial space, it is possible to detect leaks early and take appropriate action to prevent the release of hazardous materials. For example, if a leak is detected, the tank could be emptied and repaired to prevent further releases.

Overall, tank level sensors are an important part of double wall tanks because they provide a means of detecting leaks in the inner wall and ensuring the integrity of the tank. By selecting the correct sensors and maintaining them properly, it is possible to ensure the safe and reliable operation of the tank.

Learn more about level sensors

Please contact us to discuss your application