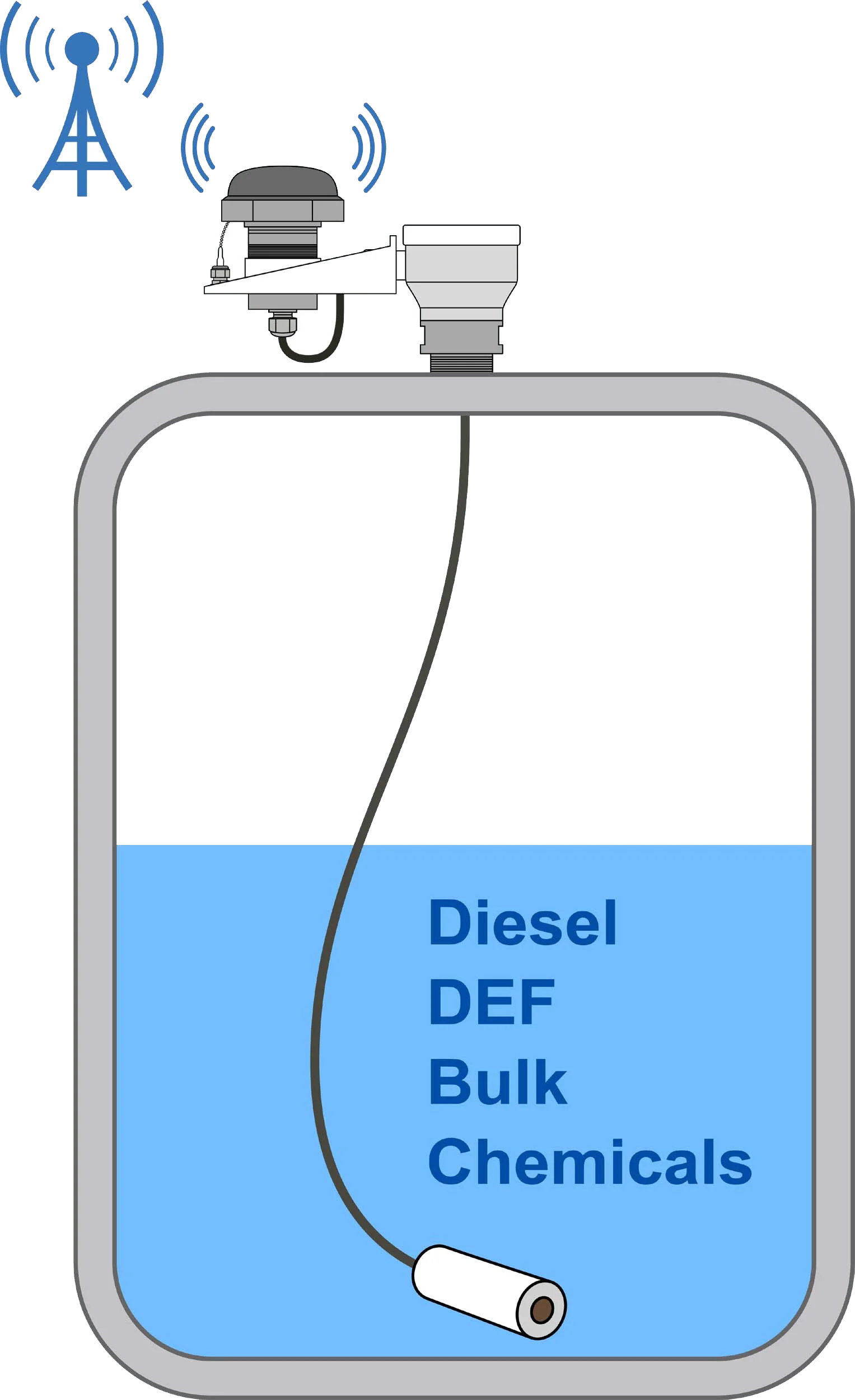

Why Use a Submersible Level Sensor on Bulk Chemicals

A submersible level sensor is a type of level sensor that is designed to be submerged in a liquid or bulk chemical. These sensors are typically used to measure the level of liquids or chemicals in tanks or other containers. The benefits of using a submersible level sensor include:

- High accuracy: Submersible level sensors are typically highly accurate and can provide precise measurements of the level of the liquid or chemical.

- Durability: Submersible level sensors are designed to withstand the harsh conditions of being submerged in a liquid or chemical and are typically made with durable materials such as stainless steel.

- Versatility: Submersible level sensors can be used to measure the level of a wide range of liquids and chemicals, including those that are corrosive or abrasive.

- Easy to install: Submersible-level sensors can be easily installed in tanks or other containers, and do not require any additional equipment or accessories.

- Cost-effective: Submersible level sensors are often less expensive than other types of level sensors, making them a cost-effective option for many applications.

- Compatibility: Submersible-level sensors can be compatible with different types of communication protocols, such as 4-20mA, HART, Modbus, Profibus, etc. which allows for easy integration into various control and monitoring systems.

- Immunity to external interference: Submersible level sensors are not affected by external factors such as pressure, temperature, vibration, and electromagnetic interference.

- easy maintenance: As the sensor is submerged in the liquid and sealed, it can be easily cleaned and maintained.

It’s important to note that submersible level sensors are typically used to measure the level of liquids, but they can also be used to measure the level of certain types of bulk chemicals that are not corrosive or abrasive.

Learn more about level sensors

Please contact us to discuss your application