Yes the Submersible Really Is The Best Liquid Level Sensor for Chemicals

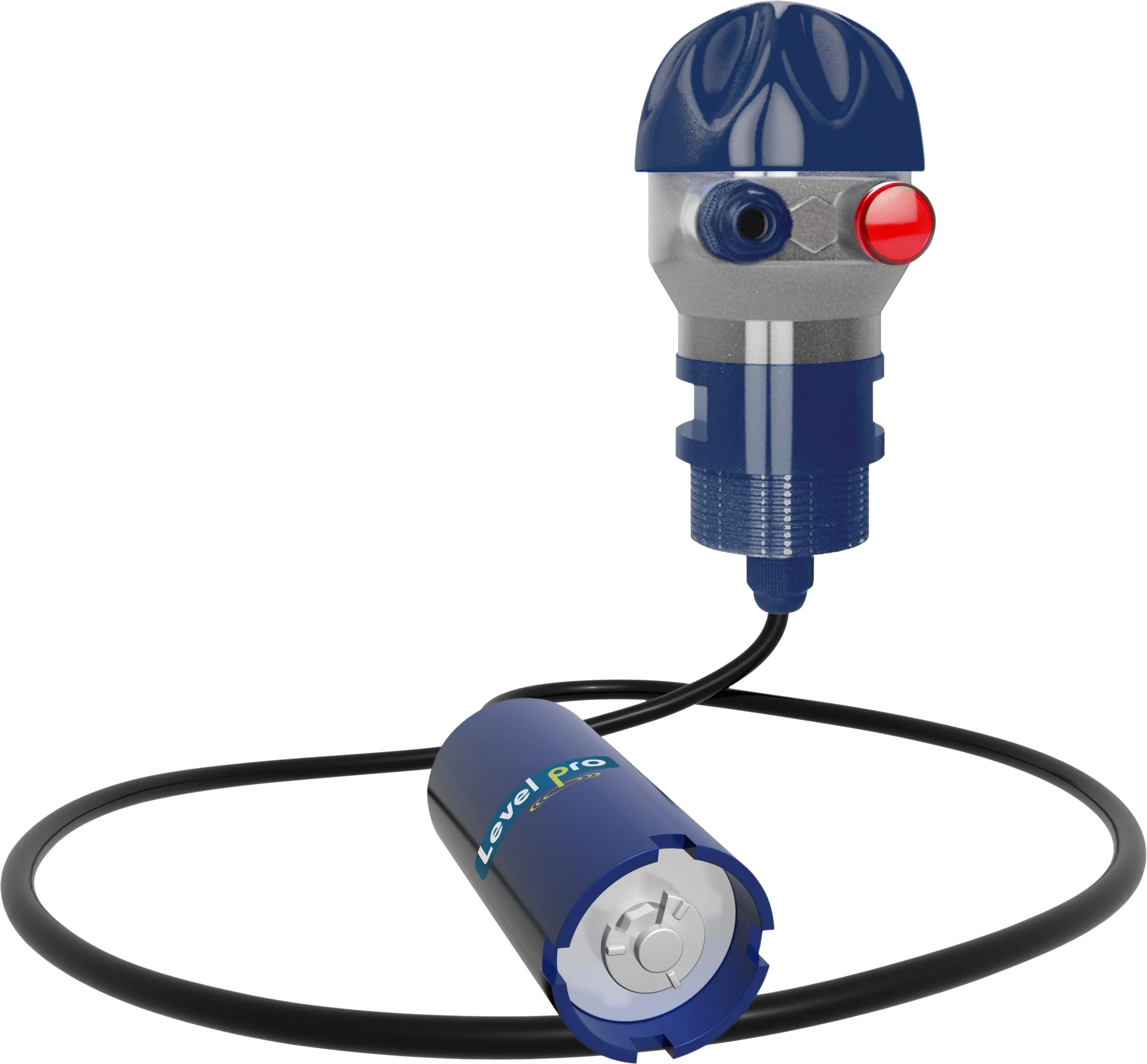

When it comes to measuring the level of liquids in chemical tanks and other industrial applications, submersible liquid level sensors are the most common type of sensor employed. They are made up of a sensor probe that is submerged in the liquid, as well as a signal transmitter that is connected to a control system and relays the information that was measured. The chemical compatibility of the liquid being monitored will determine the type of material that can be used to make the sensor probe. Some examples of possible materials include stainless steel, titanium, or PVC.

In most cases, the submersible liquid level sensor probe is connected to the signal transmitter by means of a cable. The cable may have either a two-wire or a three-wire structure, depending on the requirements of the application. The two-wire arrangement is typically favored since it is easier to implement and requires fewer resources; however, its accuracy is inferior to that of the three-wire configuration. The data from the measurements are converted by the signal transmitter into a 4-20mA loop-powered signal, which is therefore easily able to be included in a control system.

The fact that submersible liquid level sensors are immune to the effects of mist, foam, condensate, and turbulence is one of the most significant advantages they offer. Because of this, they are an excellent choice for use in chemical tanks, which frequently have such circumstances. In addition, submersible liquid level sensors can be installed with a little amount of effort and do not need to be programmed. They are also sturdy and long-lasting, qualities that make them suited for usage in demanding commercial settings.

Ultrasonic level sensors, on the other hand, are susceptible to interference from foam, mist, and condensation, all of which can result in false measurement results. In addition, ultrasonic sensors are not appropriate for use in certain applications, such as tanks containing liquids that are turbulent or environments with high levels of noise.

In addition to being accurate and dependable, radar level sensors have a higher price tag and are susceptible to interference from foam and vapor. They are more suited for applications that need a high level of accuracy, as well as tanks that are both larger and more complex.

In conclusion, the submersible liquid level sensor is thought to be the best sensor for measuring the level of chemicals in chemical tanks. This is due to the fact that it is an affordable, simple-to-install, long-lasting, and accurate solution that can be used for chemical tanks and other industrial applications.

Learn more about level sensors

Please contact us to discuss your application